Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

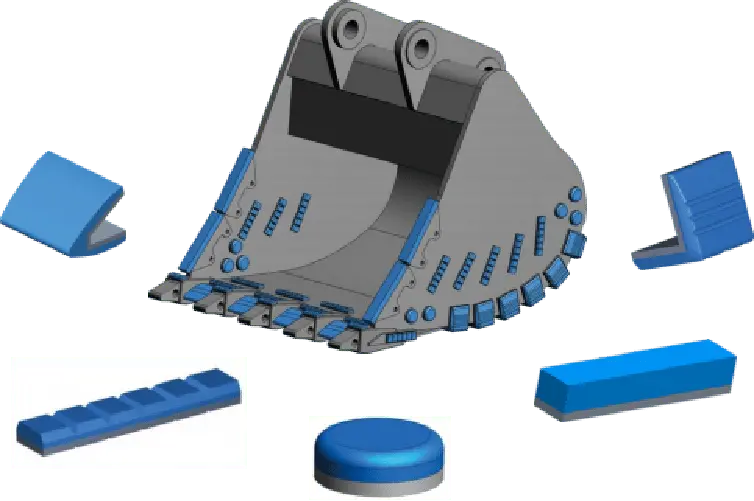

Qiming Casting has the whole bimetallic wear solution to protect the excavator bucket. The wear package including Chocky Bars, Wear Buttons, Wear Bars, Heel Shroud, Lip Shroud, Wing Shroud, and Skid Bars will provide comprehensive wear protection on the weak points on the buckets. With the whole protection solution, the service life of the bucket could be multiplied and maintenance is significantly reduced.

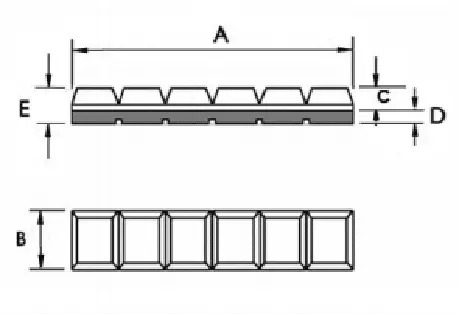

Chocky bars, also known as chocky blocks or wear bars, are a type of wear-resistant material used in various industries to protect surfaces from abrasion and impact. These bars are particularly common in applications where materials experience sliding or impact wear. The name “chocky” is derived from their use in chutes and hoppers where materials often get stuck or “chocked.”

Chocky Bars are unique block products, which can be formed and welded onto flat or curved surfaces. Chocky Bars can be used on a range of fixed plant and mobile equipment such as buckets and chute liners.

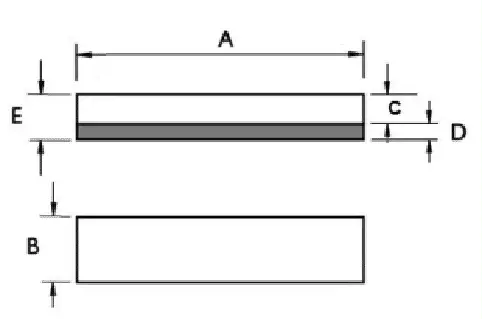

Qiming Casting supplies standard or custom sizes for customers:

| Part No. | A | B | C | D | E | Weight (kgs) |

| CB 25N | 240 | 25 | 15 | 8 | 23 | 0.90 |

| CB 40N | 240 | 40 | 15 | 8 | 23 | 1.50 |

| CB 50N | 240 | 50 | 15 | 8 | 23 | 1.90 |

| CB 65N | 240 | 65 | 15 | 8 | 23 | 2.50 |

| CB 90N | 240 | 90 | 15 | 8 | 23 | 3.50 |

| CB 100N | 240 | 100 | 15 | 8 | 23 | 3.90 |

| CB 130N | 240 | 130 | 15 | 8 | 23 | 5.15 |

| CB 150N | 240 | 150 | 15 | 8 | 23 | 6.2 |

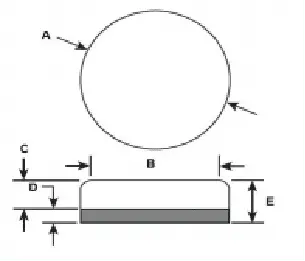

A wear button is a type of wear-resistant material used in industrial applications to protect surfaces from abrasion, impact, and wear. Similar to chocky bars, wear buttons are typically made from a combination of a wear-resistant white iron alloy and a steel backing plate. The wear-resistant alloy provides excellent hardness and toughness, while the steel backing plate adds strength and facilitates easy attachment to the surface that needs protection.

The wear button gets its name from its button-like appearance. It is essentially a small, circular or slightly domed wear-resistant insert that is welded onto surfaces that are prone to wear and tear. The buttons are strategically placed on the equipment or machinery where wear is likely to occur, providing localized protection.

Qiming Casting supplies standard or custom sizes wear button for customers:

| Part No. | A | B | C | D | E | Weight (kgs) |

| WB60 | 60 | 40 | 20 | 10 | 30 | 0.7 |

| WB75 | 75 | 55 | 20 | 10 | 30 | 1.0 |

| WB75-27 | 75 | 55 | 17 | 10 | 27 | 0.9 |

| WB90 | 90 | 70 | 20 | 10 | 30 | 1.5 |

| WB90-32 | 90 | 70 | 20 | 12 | 32 | 1.6 |

| WB115 | 115 | 95 | 20 | 12 | 32 | 2.6 |

| WB150 | 150 | 130 | 25 | 16 | 41 | 5.7 |

| WB150-32 | 150 | 130 | 20 | 12 | 32 | 4.5 |

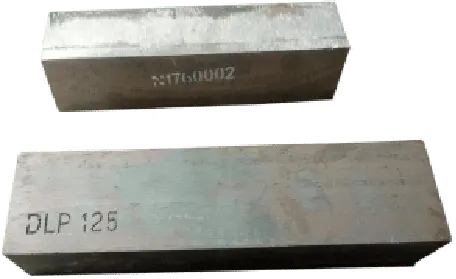

A wear bar is a component designed to resist abrasion and reduce wear in various industrial applications. It is a wear-resistant element typically made of materials that can withstand the impact and friction associated with abrasive substances. Wear bars are commonly used in equipment and machinery where surfaces are subjected to continuous wear and tear.

Qiming Casting supplies standard and custom sizes wear bars for customers:

| Part No. | A | B | C | D | E | Weight (kgs) |

| DLP 919 | 200 | 25 | 15 | 10 | 25 | 1.0 |

| DLP 1191 | 300 | 25 | 15 | 10 | 25 | 1.5 |

| DLP 295 | 153 | 38 | 25 | 8 | 33 | 1.5 |

| DLP 4 | 300 | 38 | 25 | 8 | 33 | 3.0 |

| DLP 271 | 203 | 50 | 12 | 8 | 20 | 1.6 |

| DLP 270 | 254 | 50 | 12 | 8 | 20 | 2.0 |

| DLP 508 | 190 | 50 | 20 | 10 | 30 | 2.2 |

| DLP 2199 | 65 | 50 | 38 | 12 | 50 | 1.3 |

| DLP 2265 | 115 | 50 | 38 | 12 | 50 | 2.3 |

| DLP 337 | 127 | 50 | 38 | 12 | 50 | 2.4 |

| DLP 1101 | 150 | 50 | 40 | 10 | 50 | 2.9 |

| DLP 343 | 190 | 50 | 40 | 10 | 50 | 3.7 |

| DLP 369 | 210 | 50 | 38 | 12 | 50 | 4.1 |

| DLP 125 | 230 | 50 | 38 | 12 | 50 | 4.5 |

| DLP 453 | 294 | 50 | 40 | 10 | 50 | 5.8 |

| DLP 2017 | 300 | 50 | 40 | 10 | 50 | 5.9 |

| DLP 201A | 432 | 50 | 38 | 12 | 50 | 8.5 |

| DLP 2230 | 600 | 50 | 38 | 12 | 50 | 11.8 |

| DLP 965 | 250 | 60 | 12 | 8 | 20 | 2.4 |

| DLP 184 | 150 | 75 | 29 | 10 | 39 | 3.4 |

| DLP 528 | 150 | 75 | 40 | 10 | 50 | 4.4 |

| DLP 619 | 150 | 75 | 50 | 10 | 60 | 5.3 |

| DLP 450 | 294 | 80 | 38 | 12 | 50 | 9.2 |

| DLP 451 | 194 | 80 | 38 | 12 | 50 | 6.1 |

| DLP 392/20 | 241 | 100 | 38 | 20 | 58 | 11.0 |

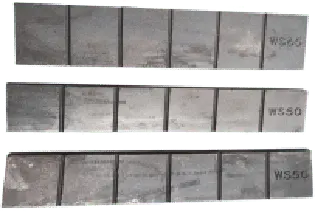

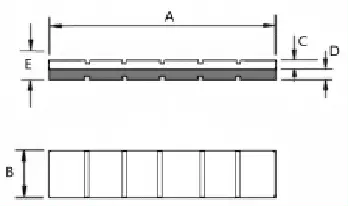

Qiming Casting Wafer Strips are metallurgically bonded to a weldable, impact-resistant backing plate. Qiming Casting Wafer Strips are easy to use and install. They can be bent, cut, and formed to suit different surfaces. The grades and sizes of Qiming Casting Wafer Strips can also be customized as per the customer’s specific need. These benefits lead to significant increases in wear life when compared to standard AR plates and less downtime and maintenance on worn parts.

Qiming Casting Proprietary: Alloyed15CRMo -Abrasion Resistant Chrome White Iron, ref ASTM A532

Qiming Casting supplies standard and custom sizes wafter strip:

| Part No. | A | B | D | E | F | Weight (kgs) |

| WS 25 | 240 | 25 | 6 | 12 | 0.6 | |

| WS 40 | 240 | 40 | 6 | 12 | 0.9 | |

| WS 50 | 240 | 50 | 6 | 12 | 1.2 | |

| WS 65 | 240 | 65 | 6 | 12 | 1.5 |

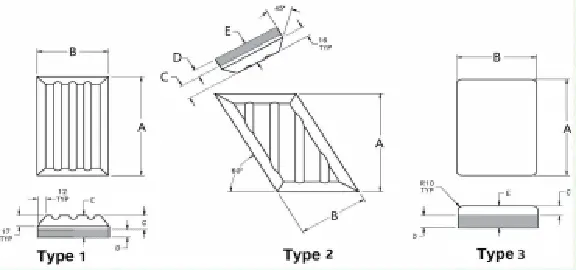

In construction equipment, a skid bar is a part designed to minimize skidding or sliding of heavy machinery on certain surfaces. It could be a wear-resistant bar or plate used to enhance stability.

Qiming Casting manufactures standard and custom sizes skid bars for customers:

| Part No. | Type | A | B | C | D | E | |

| Rectangular | |||||||

| SB 403 | 1 | 214 | 101 | 22 | 12 | 34 | |

| SB 406 | 1 | 302 | 101 | 22 | 12 | 34 | |

| SB 409 | 1 | 154 | 101 | 22 | 12 | 34 | |

| SB 205 | 1 | 279 | 75 | 22 | 12 | 34 | |

| Herringbone | |||||||

| SB 404L | 2 | 214 | 101 | 22 | 12 | 34 | |

| SB 405R | 2 | 214 | 101 | 22 | 12 | 34 | |

| SB 407L | 2 | 302 | 101 | 22 | 12 | 34 | |

| SB 408R | 2 | 302 | 101 | 22 | 12 | 34 | |

| SB 410L | 2 | 154 | 101 | 22 | 12 | 34 | |

| SB 411R | 2 | 154 | 101 | 22 | 12 | 34 | |

| Domed Edge | |||||||

| SB 412 | 3 | 250 | 150 | 20 | 25 | 45 | |

| SB 413 | 3 | 200 | 150 | 20 | 25 | 45 | |

| SB 414 | 3 | 250 | 250 | 20 | 25 | 45 | |

A bolt protector for construction and heavy equipment is a device or component designed to shield and safeguard bolts used in critical areas of machinery. Construction and heavy equipment often consist of numerous bolts that hold together various components, such as bucket teeth, cutting edges, or other wear parts. These bolts are exposed to harsh working conditions, including abrasion, impact, and debris, which can lead to wear and damage over time.

Qiming Casting manufactures standard and custom sizes bolt protectors for customers:

| Part No. | A | B | C | D | E | Weight (kgs) |

| DLP 1920 | 75 | 25 | 17 | 8 | 25 | 0.7 |

| DLP 1921 | 100 | 50 | 17 | 8 | 25 | 1.0 |

| DLP 1994 | 100 | 70 | 24 | 8 | 32 | 1.0 |

| DLP 2196 | 130 | 80 | 15 | 8 | 23 | 1.3 |

| DLP 4471 | 148 | 108 | 25 | 10 | 35 | 2.2 |

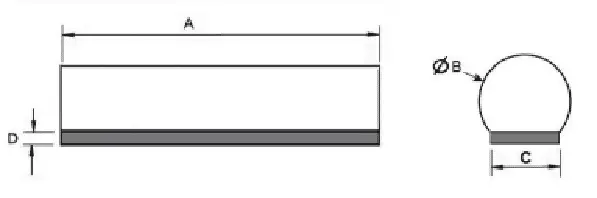

Qiming Casting manufactures standard and custom sizes roll bars for customers:

| Part No. | A | B | C | D | Weight (kgs) |

| RB4091 | 229 | 32 | 19 | 8 | 2.0 |

| RB4092 | 305 | 51 | 38 | 8 | 7.9 |

| RB4093 | 305 | 76 | 63.5 | 8 | 10.2 |

| RB4094 | 305 | 127 | 127 | 8 | 29.6 |

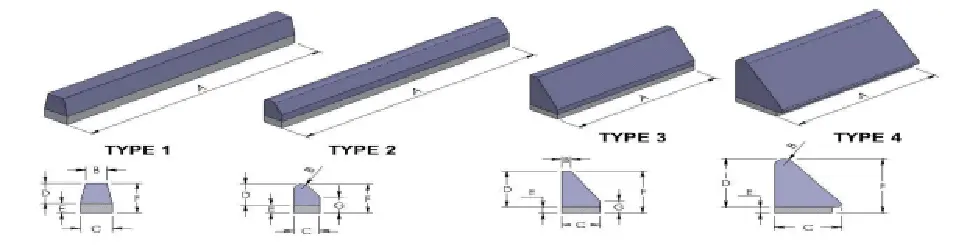

Qiming Casting Shaped Wear Bars are designed for the prevention of gouging wear and thus allow buckets and equipment to run longer requiring far less downtime for maintenance. Shaped Wear Bars are available in different shapes to suit specific applications.

Qiming Casting Proprietary: Alloyed15CRMo -Abrasion Resistant Chrome White Iron, ref ASTM A532

Qiming Casting manufactures the following sizes of shaped wear bars:

| Part No. | TYPE | A | B | C | D | E | F | Weight (kgs) |

| DLP 384 | 1 | 200 | 13 | 20 | 20 | 10 | 30 | 0.8 |

| DLP 753 | 1 | 244 | 10 | 25 | 25 | 10 | 35 | 1.4 |

| DLP 1909 | 1 | 202 | 10 | 25 | 25 | 10 | 35 | 0.9 |

| DLP 160 | 2 | 275 | 5 | 16 | 21 | 8 | 29 | 0.9 |

| DLP 947 | 3 | 150 | 10 | 40 | 60 | 10 | 70 | 2.4 |

| DLP 1414 | 4 | 125 | 10 | 70 | 80 | 10 | 90 | 4.3 |