Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

The innovator of wear components for the mining, aggregate, cement, coal, and oil & gas sectors is Qiming Casting. We are dedicated to creating solutions built to deliver long-term performance, little maintenance, and increased machine uptime. Worn components with ceramic inlays have definite benefits over conventional steel alloys. Shark skin, which uses a matrix of small, hard, tooth-like structures, is one of the most robust materials on earth, drawing comparisons to the animal kingdom. Qiming Casting produces a variety of ceramic wear components with exceptional armor-like qualities.

Ceramic inserts are designed to be extremely hard, durable, and resistant to wear, abrasion, and impact. In industrial settings, ceramic inserts are commonly used in wear parts such as cutting tools, pumps, valves, and other components. They are also used in high-wear areas of machinery, such as the liners, blades, and other parts of crushers and mills.

Are you looking for a more wear-resistant wear part? Do you want to extend the better cycle time of your wear parts? Do you want to reduce machine downtime? Ceramic inserts wear parts are your choice! Feel free to contact us!

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

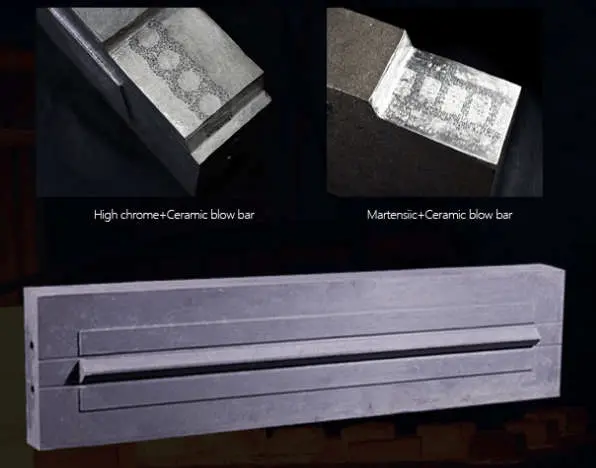

Qiming Casting manufactures ceramic inserts blow bars in two materials:

Martensitic steel is the matrix material and inserts ceramic. Martensite is a completely carbon-saturated type of iron that is made by quick cooling-off. It is only in the subsequent heat treatment that carbon is removed from the martensite, which improves the strength and wear properties. When inserted with high-hardness ceramics, the martensitic steel blow bar is dramatically enforced for wear resistance on the wear surface. This makes them the ideal solutions used in primary or secondary crushing where wear and impact resistance are both required. The lifetime is doubled or longer on martensitic blow bars without ceramic inserts.

Chrome Iron with ceramic is a premium composite metallic matrix iron with hard ceramic alloy inserts on the wear surface. The hard alloy ceramics combined with either medium chrome or high chrome iron matrix provides a significant working life advantage over standard chrome iron bars.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

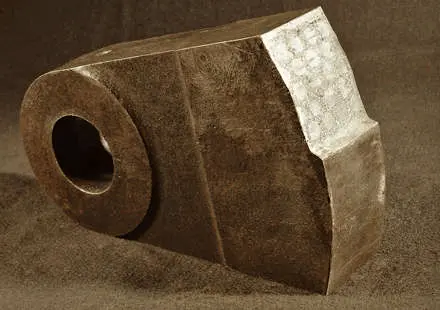

Ceramic inserts can also be used in crusher hammers to increase their durability and resistance to wear. Crusher hammers are the part of a crusher that applies an impact force to the material being crushed.

Similar to ceramic inserts in blow bars, ceramic inserts in crusher hammers are made of a hard and wear-resistant ceramic material. These inserts can help to extend the lifespan of the crusher hammers, reducing the frequency of replacement and downtime needed for maintenance and repairs.

The use of ceramic inserts in crusher hammers can also improve the efficiency and performance of the crusher, as the increased durability of the hammers allows for more consistent and effective crushing of the material being processed. Additionally, the use of ceramic inserts can help to reduce the overall cost of crusher operation over time by lowering the need for frequent replacements of the crusher hammers.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

Hammer head is widely used in crushing shales and coal gangues. Qiming Casting develops chrome white iron + ceramic hammer head to prolong its span life.

Ceramic inserts are known for their hardness, wear resistance and durability. By adding ceramic inserts to a hammer head, the hammer becomes more effective at breaking or crushing hard materials such as rocks, concrete, or metal. The ceramic inserts can withstand high impact forces and can help to reduce wear and tear on the hammer head, which can extend the life of the hammer.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!