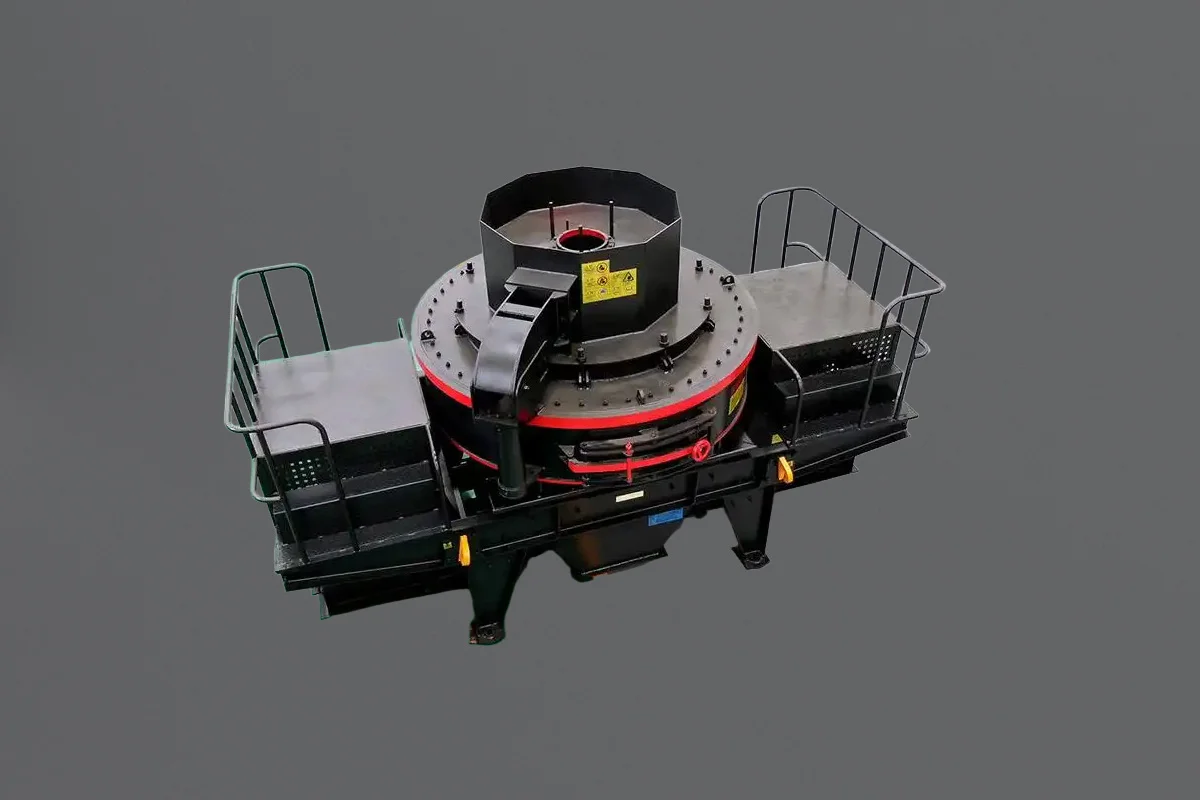

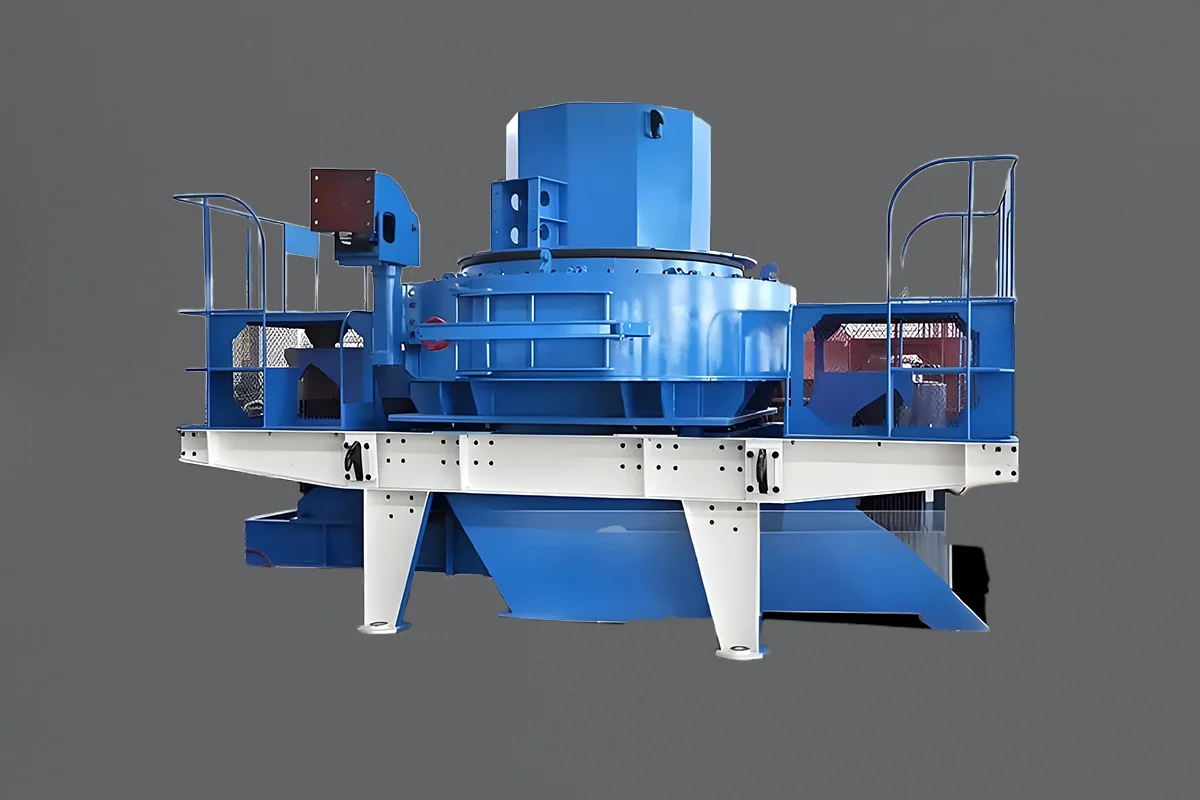

Cone Crusher Head Assembly

What is cone crusher head assembly?

A cone crusher head assembly is a component that is located at the top of a cone crusher and supports the mantle and the concaves. The head assembly is composed of several parts, including the main shaft, the head cap, the mantle, the thrust bearing, the countershaft bushing, and the inner eccentric bushing.

The main shaft is the central shaft that rotates and transmits the crushing force to the mantle and concaves. The head cap is a protective cover that is placed on top of the main shaft and provides a mounting surface for the mantle. The mantle is the stationary outer layer of the cone crusher that is made of steel and is shaped like a cone. It is responsible for crushing the rocks that are fed into the crusher.

The thrust bearing is a component that helps to absorb the crushing force and prevent damage to the head assembly. The countershaft bushing is a sleeve that is mounted on the countershaft and supports the head assembly. The inner eccentric bushing is a component that is located between the main shaft and the countershaft and helps to control the movement of the head assembly.

Together, these components form the head assembly of a cone crusher and play a critical role in the crushing process. The head assembly is typically one of the most expensive parts of a cone crusher, and it requires regular maintenance to ensure that it functions properly and provides reliable crushing performance.

How to install the head assembly?

If the head, mantle, and feed plate assemblies were removed prior to shipment, due to weight restrictions, the various parts are to be installed as follows :

- If the feed plate was installed on the head it must be removed before the head assembly can be installed in the Crusher.

- Thoroughly clean the eccentric, upper, and lower head bushing bore, head ball, and socket liner. Check all surfaces for smoothness. Remove any nicks or scratches with fine emery cloth. Examine all oil passages to be certain they are thoroughly clean.

- Liberally lubricate the outer surface of the eccentric, head bushing bores, head ball, and socket liner bearing surface. Use regular crusher lubricating oil.

- From the toolbox obtain the circular head lifting plate and thread the proper lifting ring bolt into the off-center tapped hole in the head plate. Fit the lift ring to the lock bolt. Align the attachment holes and attach the lift ring to the lock bolt with the bolt in the tooling pack.

- With a suitable lifting device, lift the head and center the assembly over the socket liner. The off-center ring bolt will create a slight unbalance so that the head assembly will be suspended at an angle. This is necessary so that the head will be suspended at the same angle as the eccentric. The high side of the head (tipped upward) must be turned so that it aligns with the thick side of the eccentric as close as possible.

- Carefully lower the head over the socket liner.

- The top edge of the eccentric is chamfered and will aid in centering the head over the eccentric. Carefully lower the head over the eccentric while, if necessary, jogging the head and lifting at points where binding may be taking place.

- When the head is properly seated with the head ball resting fully on the socket liner, remove the lifting plate from the locking bolt.

- Fit the distributor cone onto the lock bolt. Attach the cone to the lock bolt with the central bolt. Once this bolt has been tightened, fill the hole and cover the head of the bolt with silicone to protect the equipment and simplify dismantling.

If you have any problems or inquiries about cone crusher parts, contact us freely.