Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

Explore superior cone crusher liners at Qiming Casting, the foremost China Cone Crusher Liner Factory. Our advanced technology delivers precision-engineered and durable liners, surpassing industry standards. Count on our dedication to quality, innovation, and unparalleled customer service. Elevate your crushing efficiency with Qiming Casting’s high-performance cone crusher liners.

Cone Crushers Liners is the outerwear of a Cone Crush Operator. A Cone crusher operator takes on the strenuous task of crushing gigantic rocks into smaller ones. Investing in the proper protective gear becomes essential to ensure a seamless, smooth activity. You might also find Cone Crusher Liners as ‘Cone Crusher Wear Parts.’

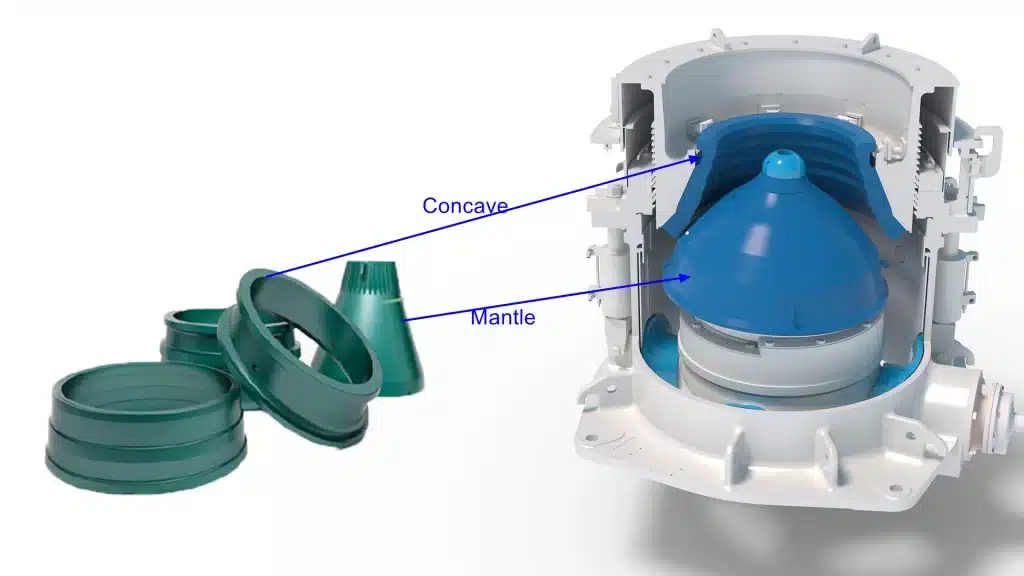

A Cone Liner is shaped as a hollow sphere with two bowl-shaped lining plates. The upper plate is categorically recognized as ‘Bowl Liner’ or ‘Concave,’ whereas the lower plate is known as ‘Cone Liner’ or ‘Mantle.’ The space between the two liners forms a crushing chamber that smartly adjusts both liners once the crushing is in progress.

Cone Liners are made of high-quality manganese steel for strong adherence upon impact. Commonly, the grades used are Mn14, Mn18, and Mn22.

There are many cone crusher liner manufacturers in the world, so why should you choose Qiming Casting? There are some reasons:

Different cone crushers have different working conditions. Using different cone liners based on working conditions can extend wear parts’ lifespan and minimize downtime.

Qiming Casting is available in various materials:

Manganese remains one of the top choices because of its durability and high resistance. The wear liner is ideal and people have used it in mining for over 100 years. Because of its property of hardening on impact, it remains one of our best-selling Cone Crusher Liners.

You can now choose from our production of various graded manganese steel cone crusher liners:

Learn more about manganese steel casting→

Manganese steel wear has a shorter life and cannot survive harsh working conditions, especially when crushing copper ore. We introduced micro-alloy crusher liners to ensure the same efficiency with longer wear time.

We make our cone crusher liner with molybdenum nickel, which enhances the structure of the casting. Our liners have a mix of manganese and carbon to strengthen the casting made of high manganese steel.

Our innovative micro-alloyed crusher liners give the same output with longer wear time. We offer different graded alloys that behave differently under various working conditions. Based on customer feedback, micro-alloy liners are better and last 20-30% longer than Mn22 liners.

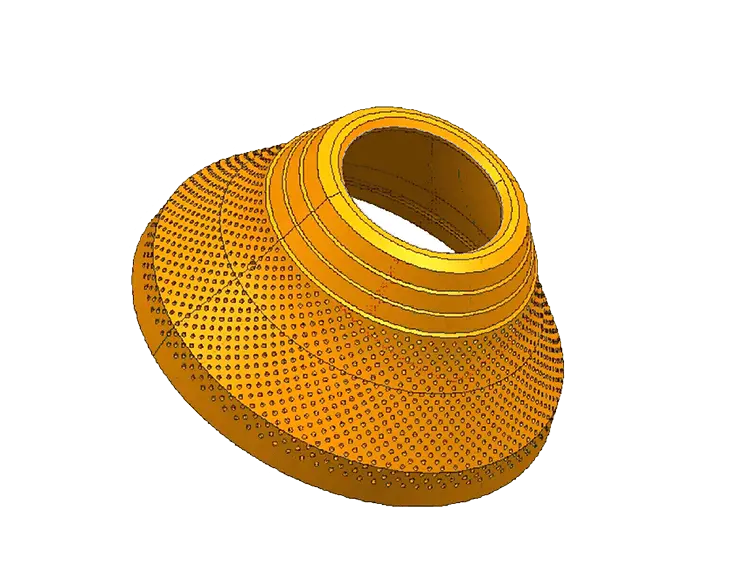

Designed explicitly by Qiming Casting engineers for crushing ultra-hard stones. Here is how our titanium carbide Inlay Cone Crusher Liner will work;

As the stone enters the crushing chamber, the protruding titanium carbide rods are the first to come into contact with the stone. Because of the ultra-hardness of the titanium carbide rods, the titanium carbide rods wear extremely slowly. On the other hand, the working surface of the high manganese steel, which is the substrate, gradually contacts the stone. When the protruding part of the titanium carbide rod wears, it hardens the working surface of the high manganese steel.

The Benefits of Using Titanium Carbide in Mining Tools

Our customers say that cone crusher liners with titanium carbide last twice as long as regular steel liners.

Learn more about TIC inserts wear parts→

After more than 20 years of accumulation, Qiming Casting has thousands of patterns. Our company has all the rights to use these patterns, which can reduce your’ procurement costs.

We will keep records for all products made in Qiming Casting and provide customers with quality inspection reports.

For example, below are our quality inspection reports for the Mn18Cr2 mantle:

Qiming Casting has a professional technical and QA team and regularly provides vocational skills training to employees.

There are some study cases of our liners for cone crusher: