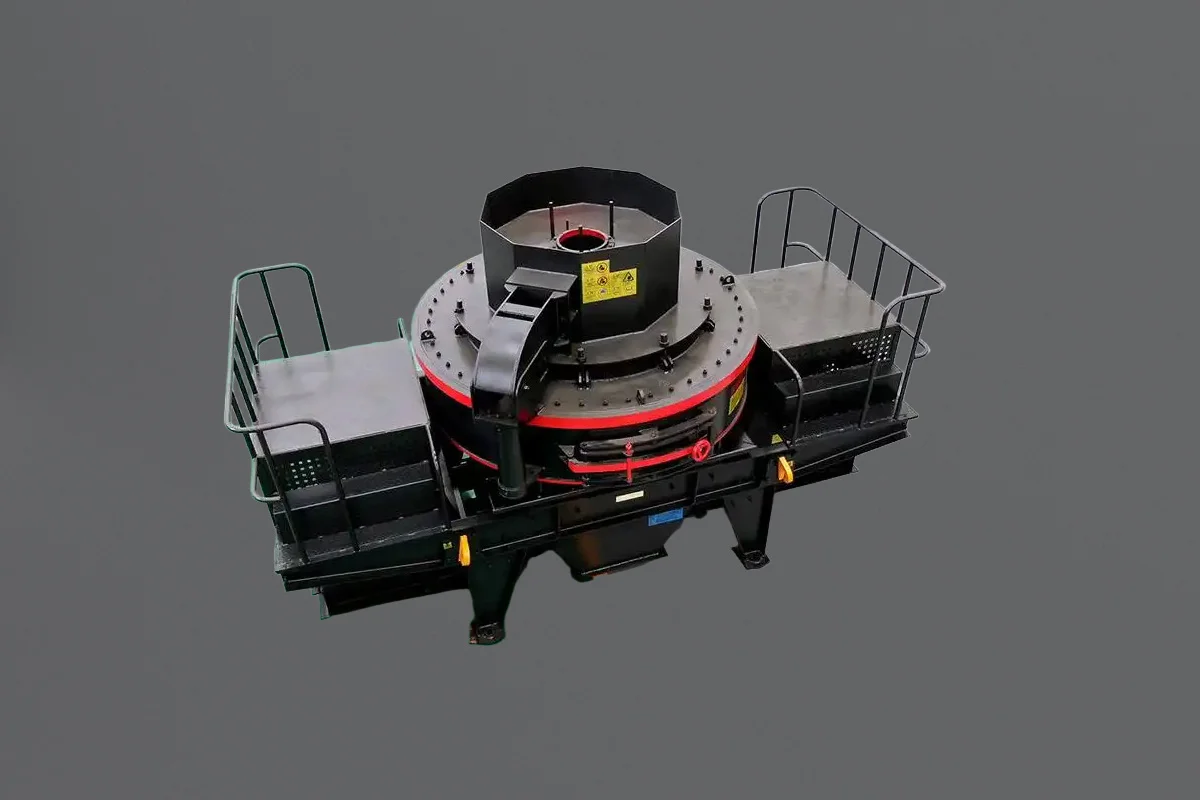

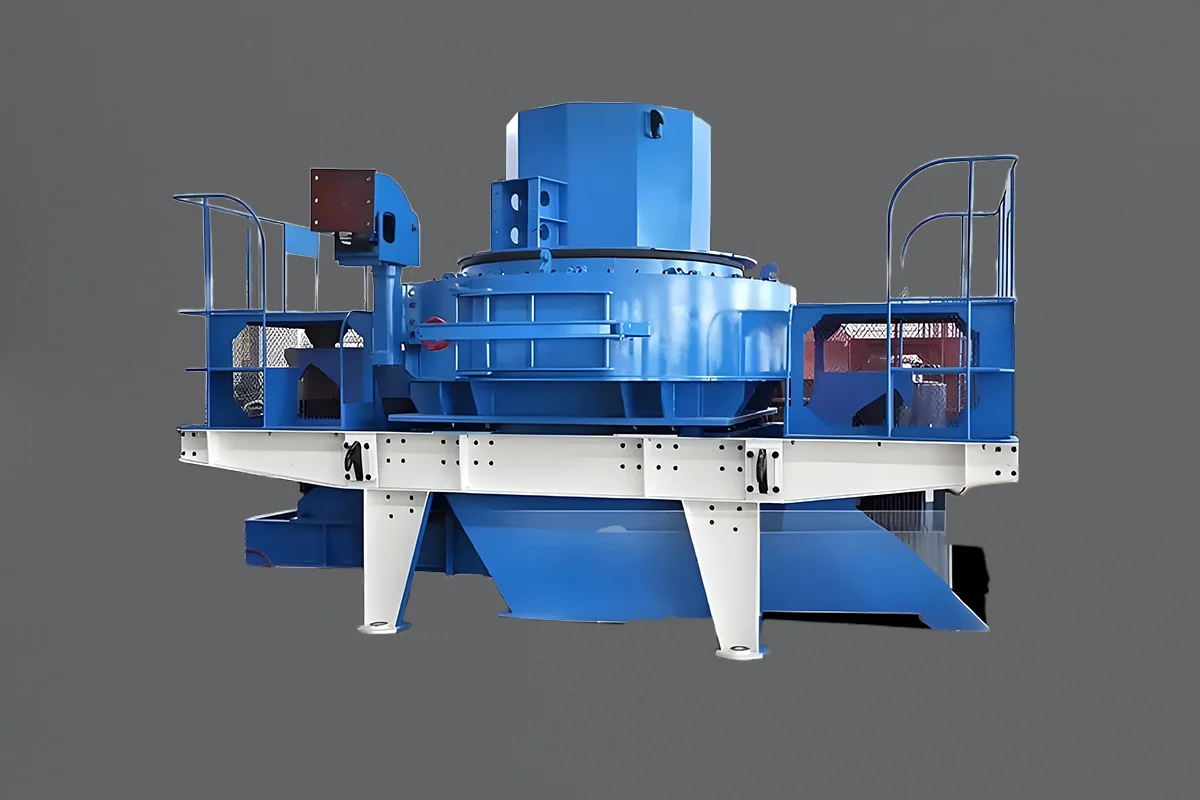

Cone Crusher Socket Assembly

The socket with the socket liner supports the head assembly and transmits the crushing force to the main frame. The socket is held rigidly to the main shaft by an interference fit and a series of capscrews installed around the perimeter of the socket. The socket liner which is dowelled to the top of the socket provides the bearing surface for the head ball bolted to the underside of the head. The grooved, spherical bearing surface of the socket liner is thoroughly lubricated by oil under pressure pumped through interconnecting oil passages between the main shaft and socket.

Socket Assembly Instructions

If the socket and socket liner were removed in order to allow for the removal of the eccentric for shipping purposes, first install the eccentric assembly and then proceed as follows:

- From the toolbox, take the three alignment studs and thread them into the tapped holes at the top of the main shaft.

- Install two ring bolts into the socket and connect them to a lifting device of suitable capacity.

- Heat the socket, above ambient temperature, and install it on the main shaft as quickly as possible.

- Lower the socket over the alignment studs and onto the shaft. Be sure the socket is tightly seated against the top of the main shaft. Check with a feeler gauge through the access holes in the side of the socket to make sure the socket is seated flat on the main shaft (no clearance).

- Remove the alignment studs and install capscrews with lock washers through the socket into the tapped holes in the main shaft. Alternately tighten the capscrews a small amount until they are tight.

- After rechecking the torque of the socket capscrews when the socket has cooled, REHEAT the socket, above ambient temperature, before installing the socket liner.

- Install ring bolts into the tapped holes on the outside diameter of the socket liner.

- Attach socket liner ring bolts to a suitable lifting device.

- Position socket liner so that the clearance holes in the bottom of the liner go over the locating dowels in the socket. Then lower the liner onto the socket.

Cone Crusher Socket Assembly Maintenace

Socket liner replacement

Oil grooves in the spherical surface of the socket liner are to be used to determine when the liner requires replacing. Measure the socket liner. When the bearing surface of the socket liner has worn to where the oil groove depth is reduced to 2.5 mm (0.098 inches) the liner should be replaced. If socket liner to socket fit becomes slightly loose, it does not matter because dowels will prevent socket liner from turning.

Replace socket liner as follows:

- Install three jackscrews in the tapped holes in the socket liner.

- Alternately tighten the jackscrews in small amounts. If necessary, the UPPER portion of the socket can be heated to assist in the removal of the liner.

- Remove jackscrews and install ring bolts in outside diameter of socket liner.

- Attach a suitable lifting device and remove worn socket liner.

- The new socket liner is installed by heating the socket. Heat the UPPER portion of the socket, above ambient temperature, which will increase the socket bore enough to allow the socket liner to drop right in.

- Align clearance holes in the bottom of the socket liner over the locating dowels in the socket and lower liner into socket bore. BE CERTAIN THE LINER IS FULLY SEATED ON THE SOCKET.

Socket removal

The socket can be removed to allow for the removal of the eccentric or the replacement of other parts. To remove the socket, proceed as follows:

- Remove the three capscrews that attach the socket to the main shaft.

- Install the three jackscrews in the tapped holes in the socket. Heat the LOWER portion of the socket on the outside diameter while alternately tightening the jackscrews in small increments. When the socket is heated, above ambient temperature, the socket will have expanded sufficiently to be free of its interference fit on the shaft. Remove jackscrews.

- Install ring bolts in the top of the socket.

- Attach suitable lifting device and remove the socket.

If you have any questions or inquiries about cone crusher parts, contact us freely.