Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

Qiming Casting is one of the leading suppliers of durable wear solutions, supplying over 30 years of high-grade, high-quality chrome steel and Metal Matrix Composite blow bars for all kinds of popular brands. Our diverse teams have engineered the finest blow bars, innovatively designed to withhold high impact and abrasion.

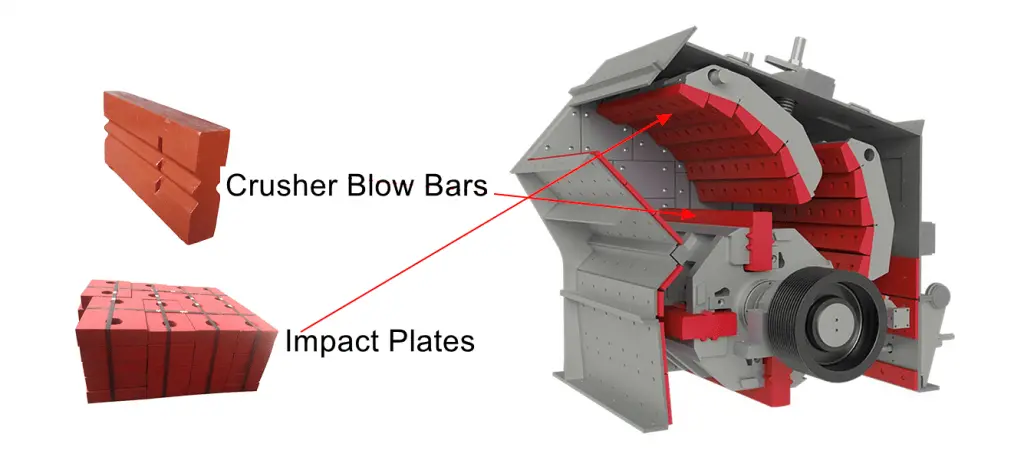

Crusher blow bars, or ‘impact blow bars,’ are crucial wear items for impact crushers. A blow bar diverts the material towards the crushing chamber. The material fractures into smaller segments as soon as it comes in contact with the impact wall. They ensure the machine is appropriately undergoing the crushing process. Crusher blow bars must be replaced in time to avoid damage to other integral parts of the machinery.

A crusher blow bar is used in horizontal shaft crushers and is mounted on top of the rotor, stacked in groups of 3 or 4 pieces. Once the machine starts, the material comes in contact with the bar and is immediately crushed. A crusher blow bar is made up of high-resistance steel with various other materials that can be customized in accordance with machinery specifics and the client’s needs. A crusher must first be made in light of what will accurately match your machinery’s profile, which is what we do here at Qiming Casting.

Qiming Casting is one of the leading front players in the mining industry, distributing quality mining goods for over 30 years. We offer specific customized shapes and metallurgical material specifications to match diverse operating processes and crushers. Our consistent quality has made us one of the biggest suppliers of high chrome blow bars in the Middle East and Spain.

We offer a range of engineered crusher blow bars tailored to the details of your machinery profile. Our team conducts a thorough specification test on your machine to create customized blow bars.

It’s important to note the material used in your crusher blowbars. The composition of materials determines whether the blow bar would be an adequate fit against the abrasive material.

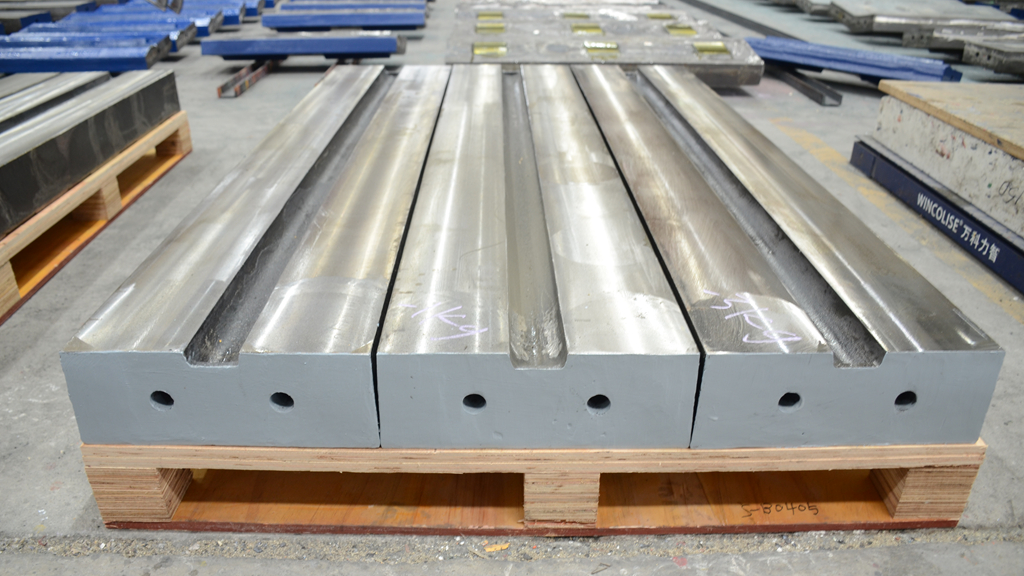

Every delivered blow bar is made of high-strength, wear-resistant material. Some of our most independent materials currently on the market are;

If you need any types of crusher blow bars, please send us your inquiry part number or drawings. On the other hand, we can offer the OEM/ODM services of our products. The product can be customized according to your personalized requirements or based on your crusher working conditions. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

You can now select from various Qiming Casting wear parts supplied to some of the biggest company chains around the globe. Our highest-quality blow bars offer double resistance, impact, and performance longevity.

Chrome steel bars are more popular amongst our clients, especially in the Middle East. Chrome is used in manufacturing products that can withstand highly abrasive crushing processes. Because Of their splintery texture, they are best at fracturing more enormous rocks. They can also aid in shredding other coarse materials smaller in feed size. We offer all kinds of graded chrome bars to match your product needs.

Learn more about Chrome steel casting→

High chrome bars are best suited for crushing natural rocks or asphalt. This is mainly due to their resistance against stubborn, difficult-to-break rocks. Compared to martensitic ceramic hammers, their title consistency makes them an excellent choice in handling uncrushable contaminants such as drilling bit, tramp, iron, rebar, and milling teeth.

We recommend our customers invest in chrome steel bars if they have smaller feeds.

Middle chrome bars accommodate larger feeds, offering a range of potential crushing materials. They are an excellent choice to crush less abrasive material in larger quantities. It could also fulfill asphalt crushing. Often, customers mistake low chrome bars for recycling purposes, which is what high chrome bars are best used for.

Our low chrome bars are best known for crushing concrete and more extensive materials. They offer excellent fatigue resistance to a mixture of rebar and steel. However, there might be better choices than low chrome bars for highly coarse materials.

Metal Matrix Composite (MMC) blow bars are components used in the construction and mining industries, particularly in crushing equipment such as impact crushers. These blow bars are a type of wear-resistant material designed to enhance the performance and durability of the crushing machines.

Traditional blow bars are typically made of high-chrome white iron, which is known for its hardness and abrasion resistance. However, Metal Matrix Composite blow bars take the design a step further by incorporating a matrix of different materials. The matrix often consists of a metal alloy combined with ceramic particles or other reinforcing materials.

Learn More about Metal Matrix Wear Parts →

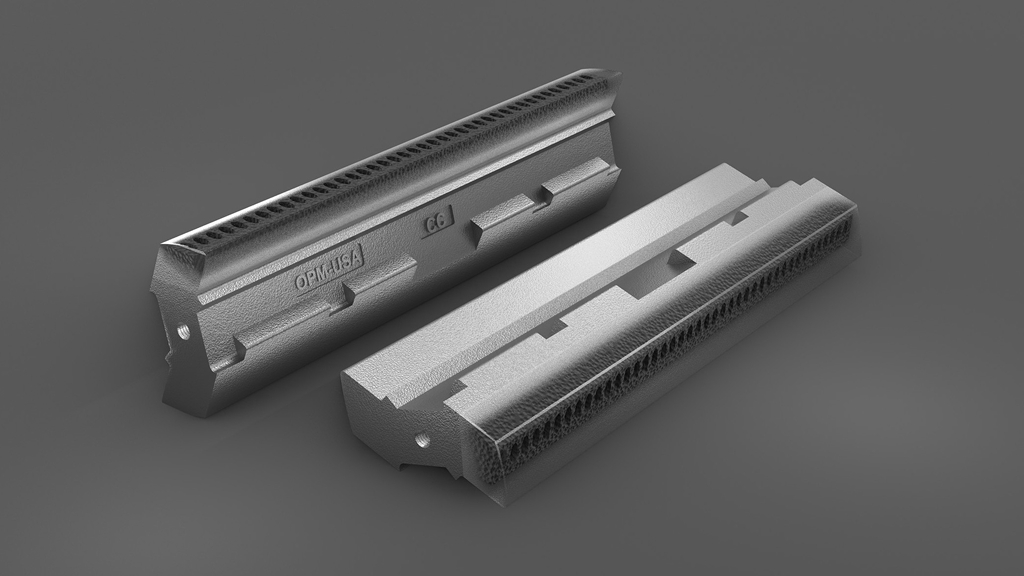

Martensitic ceramic blow bars are white iron, ceramic, and martensitic steel. Maternistis is carbon-dense iron and has high resistance properties. When combined with high-graded ceramics, martensitic ceramic reduces the risk of damage, increasing blow bars’ longevity by 60%.

Martensitic ceramic blowbars are best for recycling purposes. They are also popular amongst our clients for primary and secondary crushing.

Learn more about Martensitic Ceramic Blow Bars→

When combined with ceramic, Chrome makes a much more durable crusher blow bar mainly because it outfits ceramic inlays. However, they are best used in supporting lower, smaller feed sizes.

Chrome Iron with Ceramic is a premium composite metallic matrix iron with rigid ceramic alloy inserts on the wear surface. The rugged alloy ceramics combined with medium or high chrome iron matrix provides a significant working life advantage over standard chrome iron bars. Due to its unique composition and versatile benefits, we often recommend that our clients invest in chrome ceramic blowbars to crush the most abrasive material.

Learn more about Chrome Ceramic Blow Bars→

TIC inserts blow bars, Manganese+Tic carbide blow bars are made of manganese steel with Tic carbide inserts, widely used on primary impact crushers crushing the limestones in cement plants or quarry plants.

Manganese blow bars are mainly used in primary crushing, where feed material is typically large in size and, to a lesser degree, insecondary crushing.

The use of manganese blow bars with an innovative insert has been proven to increase service life by up to 100%.

Learn more about TIC Inserts Blow Bar →

| Qiming Casting Crusher Blow Bars Pattern List | English | PDF(129KB) | DOWNLOAD |

| Martensitic + Ceramic Blow Bars Quality Control Reports | English | PDF(423KB) | DOWNLOAD |

| Chrome + Ceramic Crusher Blow Bars Quality Control Report | English | PDF(440KB) | DOWNLOAD |