Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

Qiming Casting is one of the leading suppliers of durable wear solutions, supplying over 30 years of high-grade, high-quality manganese steel and TIC inserts manganese steel for all kinds of popular brands.

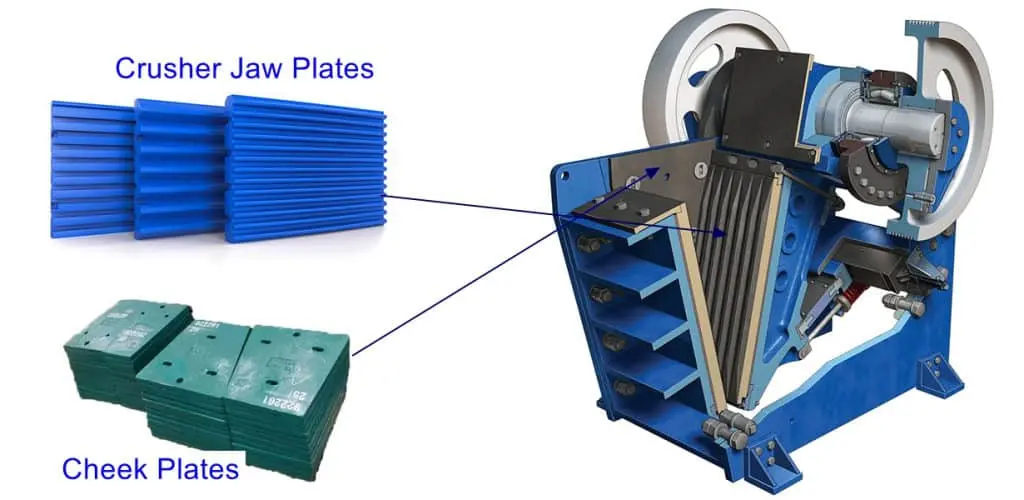

A crusher jaw plate protects and supports the jaw crusher. A jaw plate is the most frequently changed wear part, so ensuring a quality graded jaw crusher is crucial. Jaw plates, also called ‘jaw dies, ‘ are often made of a mixture of graded composite or high-resistance steel.

Working Principles

Usually, in a conventional crushing operation, there are two jaw plates of moveable and stationary jaws. These jaws are located on the opposite sides of the crushing chambers. To fully segment and fracture the material, the moveable jaw plate works reciprocally to press the material against the fixed plate. The material continues to be crushed on the fixed jaw until refined enough to get through the jaw gap.

Our team of experts has specially engineered our high-strength and resistant crusher jaw plate liners for a seamless crushing experience. Our double wear resistance technology makes our crusher jaw plates much more efficient than ordinary high manganese steel liners.

With over 30 years of proven record of being one of the best mining tools suppliers worldwide, Qiming Casting offers innovative mining solutions customized to the very detail to best suit your machinery profile.

Our Premium Crusher Jaw Plates features;

If you require any type of crusher jaw plates, kindly send us your inquiry along with the part number or drawings. We are pleased to offer OEM/ODM services for our products. Our products can be customized as per your personalized requirements or based on the working conditions of your crusher. Please provide us your design documents or share your ideas, and our R&D team will take care of the rest.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

You can now select from various Qiming Casting wear parts supplied to some of the biggest company chains around the globe. Our highest-quality of manganese and titanium carbide plates offer double resistance, impact, and performance longevity.

Manganese remains one of the top choices due to its durability and high resistance. It is an ideal wear liner and has been used in mining for over 100 years. Due to its property of hardening on impact, it remains one of our best-selling Cone Crusher Liners.

You can now choose from our production of various graded manganese steel crusher jaws:

Learn more about manganese steel casting→

Our titanium Carbide Jaw Plates are most famous in the Australian market. Titanium carbide is one of our clients’ most favored crush materials worldwide, primarily due to its ability to optimize the crushing process.

The way we incorporate titanium inlays is much different than other traditional suppliers. Titanium carbide jaw plates are less impact-resistant than steel jaw plates, which helps in the crushing operation.

After examining and matching with machinery specifics, we create complex inlays to fully augment and assist machinery operations. Once our team has investigated your machinery and operation personnel in-depth, they will determine where to apply the titanium carbide plates based on the liner’s maximum wear zone.

The Benefits of Using Titanium Carbide as Crusher Jaw Plates;

Learn more about TIC inserts wear parts→

| Quality Control Report for Crusher Jaw Plates | English | PDF(5MB) | DOWNLOAD |

| Qiming Casting’s Crusher Jaw Plates Pattern List | English | PDF(100KB) | DOWNLOAD |