Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

Qiming Casting is one of the top pioneers of supplying tailored, graded durable, and wear-resistant Gyratory Crusher Liners. With over 30 years of experience in manufacturing quality minings products, we offer the finest rush Liners innovatively designed to withhold high impact and abrasion.

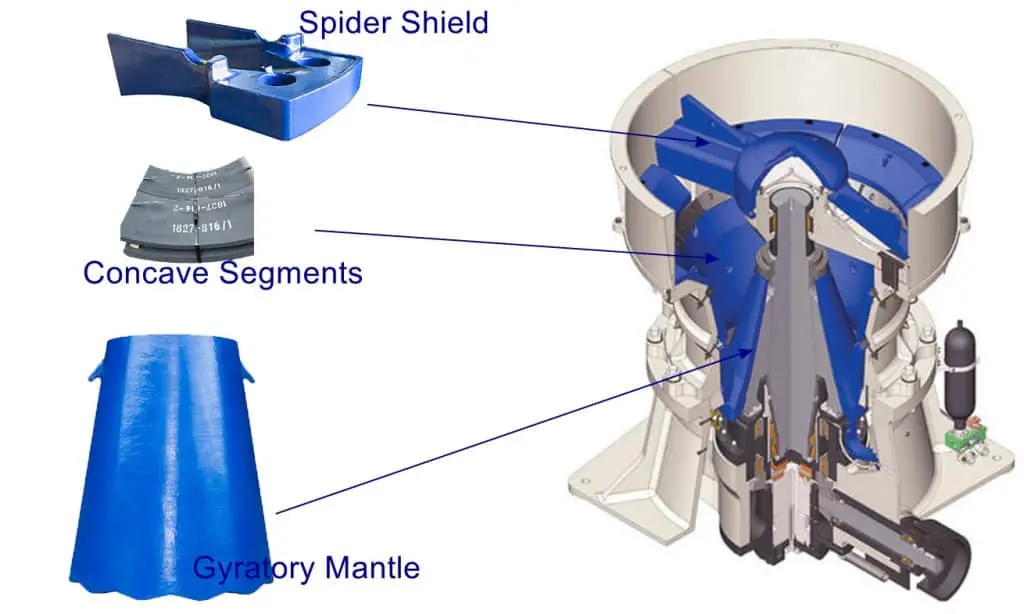

Gyratory crusher liners are essential for protecting the crusher’s mainframe, in order to protect the crusher’s longevity and service life. A gyratory crusher is gigantic and has a large capacity to crush stones. It is a hollow body of a solid cone with a revolving shaft and vertical sloping sides. Most of the material that goes into gyratory crushers is abrasive and can damage the mainframe of the machinery.

Working Principles

Gyratory crusher liners are made of high manganese steel to withstand high impact and resistance. This acts as protective wear, without compromising the efficacy of the crusher. Manganese steel is one of the best materials to use in any mining material due to its unique properties. A manganese steel on impact hardens, making it most suitable for abrasive crushing.

A durable crusher liner will help improve the efficiency of the machinery, ensuring crushing productivity and longer service life. High-graded quality manganese gyratory crusher liners reduce shutdown time maintenance and prevent profit loss.

You can now experience the high productivity of your gyratory crusher with our premium high-grade manganese gyratory crusher liners. Qiming Casting is one the longest-standing mining companies to manufacture high-graded manganese steel, alloy steel, and high chrome steel gyratory crusher liners across China.

With over 30 years of proven record of being one of the best mining tools suppliers around the world, Qiming Casting offers innovative mining solutions customized to the very detail to best suit your machinery profile.

Our Premium Gyratory Crusher Liner Features;

If you need any types of gyratory crusher liners, please send us your inquiry part number or drawings. On the other hand, we can offer the OEM/ODM services of our products. The product can be customized according to your personalized requirements or based on your crusher working conditions. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

You can now select from various Qiming Casting Crusher Liners made up of the highest quality of manganese, combined with alloys, and offer double resistance, impact, and performance longevity.

Manganese is the most favorable material engineered at Qiming Casting due to its excellent tolerance for abrasive material. It is tough and wear-resistant which enables the crushing throughput process to be more efficient and productive.

Our mantle liner design varies from piece to piece. It can easily accommodate large one-piece to two and three-pieced mantles for optimum crusher performance.

Our innovative gyratory mantle liner is reliant on key materials used in crushing high-abrasive stones. Manganese steel is best known for wear resistance, high tensile strength, and work-hardening ability to effectively withstand the rigorous crushing process.

Our clients who have customized gyratory crush liners have reported improved machine performance, less maintenance cost, and increased wear-life value after investing in our tailored crush liners.

The Benefits of Using Manganese Steel for Mantle;

Learn more about manganese steel casting→

Titanium carbide Inlay rods are one of the most favored crush liners by our clients around the world as it enhances manganese hardness making it an ideal material combination to be used in extreme and harsh environments.

The way we incorporate titanium inlays is much different than other traditional suppliers.

After examining and matching with machinery specifics, we create hard inlays to fully augment and assist machinery operations. Once our team has performed an in-depth investigation of your machinery and operation personnel, they will determine where to apply the titanium carbide rod inlays based on the liner’s maximum wear zone.

The Benefits of Using Titanium Carbide as Crusher Liners;

Learn more about TIC inserts wear parts→

| Gyratory Crusher Liners Pattern List | English | PDF(41.7KB) | DOWNLOAD |