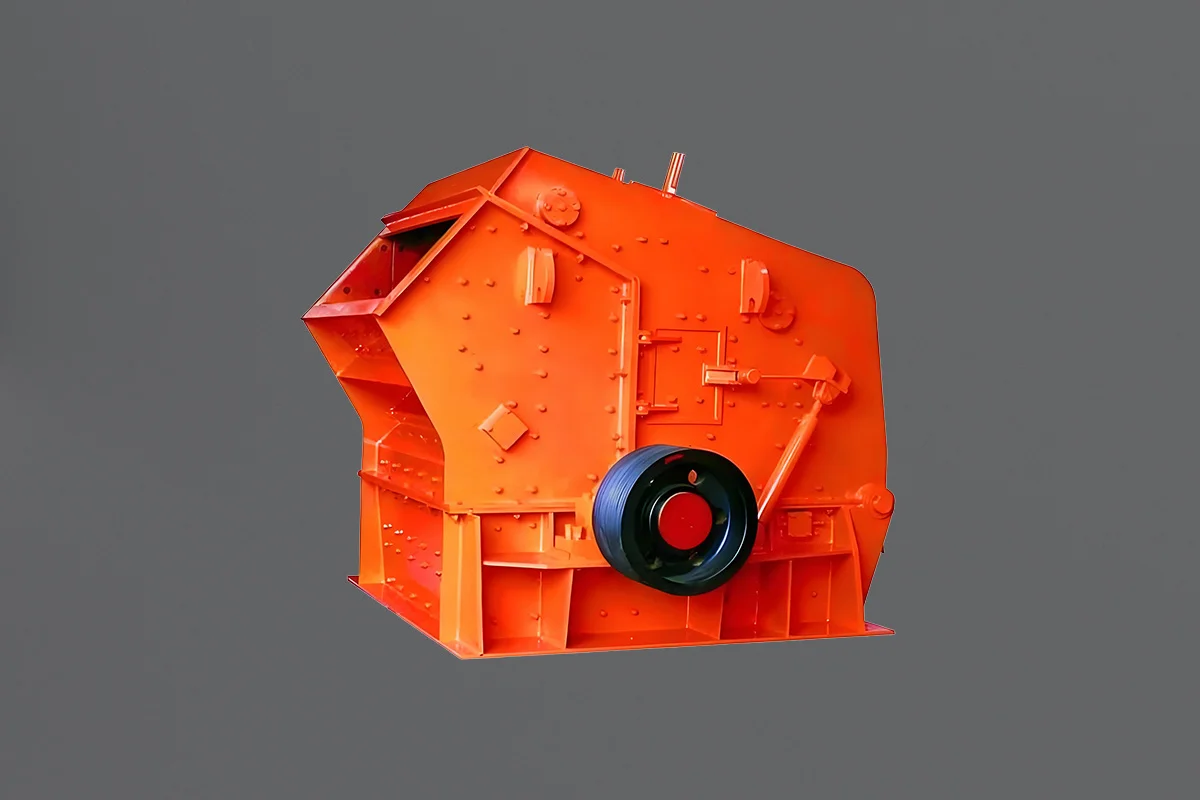

What is PF1210 Impact Crusher?

PF1210 impact crusher is very popular in the Chinese market. The leading manufacturers are Shanghai SBM and Henan Limining.PF Impact Crusher uses impact energy to crush the materials. The materials entering from the inlet impact the blow bars on the rotor and would be crushed under the high-speed impact of the blow bars. The crushed materials would be thrown back to impact plates for crushing again.

Product Parameter

- Rotor size (mm): Φ1250×1050

- Feed port size (mm): 400×1080

- Maximum feed size (mm): 350

- Processing capacity (t/h): 60-120

- Power (kW): 110

- Overall dimensions (mm): 2590×2050×2810

PF1210 Impact Crusher Parts List

| PF1210 Impact Crusher Parts List | |||||||

| Series | Part Number | Description | Specification | Material | PCS | Weight(Kg) | Location |

| 1 | PF1210-01-04 | Conical Flange | 210×210×57 | Grey Cast Iron | 4 | 11 | Pendant |

| 2 | PF1210-01-05 | Spring | Φ20×Φ120×306 | Alloy Steel | 4 | Pendant | |

| 3 | PF1210-02-01-05 | Support suspension shaft | Φ75.5×1120 | Quality Carbon Steel | 2 | 44.8 | Support Frame Assembly |

| 4 | PF1210-02-01-06 | Support adjusting shaft | Φ75.5×980 | Quality Carbon Steel | 2 | 39.2 | Support Frame Assembly |

| 5 | PF1210-02-02 | Impact Plates | 338×168×102.6 | Manganese Steel | 36 | 29.4 | Support Frame Assembly |

| 6 | PF1210-02-03 | Impact Plates Nuts | Φ36×135 | Quality Carbon Steel | 72 | Support Frame Assembly | |

| 7 | PF1210-04-08 | Square steel platen | 170×170×16 | Carbon Constructional Steel | 6 | Cavity Assembly | |

| 8 | PF1210-04-09 | Side plates1 | 804×414.6×30 | Manganese Steel | 2 | 39 | Cavity Assembly |

| 9 | PF1210-04-10 | Side plates2 | 348×348×60 | Manganese Steel | 2 | 21.5 | Cavity Assembly |

| 10 | PF1210-04-11 | Side plates3 | 348×278×60 | Manganese Steel | 34 | 22.5 | Cavity Assembly |

| 11 | PF1210-04-12 | Side plates4 | 348×330×60 | Manganese Steel | 2 | 21.5 | Cavity Assembly |

| 12 | PF1210-04-13 | Side plates5 | 348×348×60 | Manganese Steel | 27 | 27.5 | Cavity Assembly |

| 13 | PF1210-04-16 | Side plates6 | 348×348×30 | Manganese Steel | 2 | 18.5 | Cavity Assembly |

| 14 | PF1210-04-17 | Side plates7 | 348×208×30 | Manganese Steel | 2 | 7.5 | Cavity Assembly |

| 15 | PF1210-04-18 | Side plates8 | 278×258×30 | Manganese Steel | 2 | 15 | Cavity Assembly |

| 16 | PF1210-06-01-01 | Side plates9 | 348×278×30 | Manganese Steel | 2 | 20 | Cavity Assembly |

| 17 | PF1210-04-19 | Square steel | 95×95×1265 | Manganese Steel | 3 | 84.7 | Cavity Assembly |

| 18 | PF1210-05-02-05 | Shaft sleeve for rotating arm | Φ50×Φ34×45 | Quality Carbon Steel | 4 | 26.5 | Welding Table |

| 19 | PF1210-08 | Rotor assembly | / | 1 | / | Rotor Assembly | |

| 20 | PF1210-08-01 | Bearing outer cover | Φ320×Φ208×45 | Common Cast Steel | 1 | 21.5 | Rotor Assembly |

| 21 | PF1210-08-02 | Shaft end gland | Φ155×Φ142×28 | Carbon Constructional Steel | 1 | Rotor Assembly | |

| 22 | PF1210-08-03 | bearing sleeve | Φ320×Φ225×95 | Common Cast Steel | 2 | 43 | Rotor Assembly |

| 23 | PF1210-08-04 | Bearing inner gland | Φ320×Φ158×56 | Common Cast Steel | 2 | 27 | Rotor Assembly |

| 24 | PF1210-08-05 | Axle box maze cover | Φ229×Φ140×61 | Common Cast Steel | 3 | 12 | Rotor Assembly |

| 25 | PF1210-08-06 | Rotor outer gland | Φ360×32 | Common Cast Steel | 2 | 18 | Rotor Assembly |

| 26 | PF1210-08-07 | Rotor shafts | Φ220×1938 | Alloy Steel | 1 | 750 | Rotor Assembly |

| 27 | PF1210-08-08 | Rotor body | ??×1000 | Welding Parts | 1 | Rotor Assembly | |

| 28 | PF1210-08-08-01 | beam barrel | Φ460×Φ330×702 | Common Cast Steel | 1 | 535 | Rotor Assembly |

| 29 | PF1210-08-08-02 | web plate 1 | 860×860×80 | Carbon Constructional Steel | 2 | / | Rotor Assembly |

| 30 | PF1210-08-08-03 | web plate 2、3 | 860×860×80 | Carbon Constructional Steel | 2 | / | Rotor Assembly |

| 31 | PF1210-08-08-04 | positioning block | 700×34×24 | Carbon Constructional Steel | 1 | / | Rotor Assembly |

| 32 | PF1210-08-08-05 | retaining iron | 1000×182×150 | Common Cast Steel | 4 | 190 | Rotor Assembly |

| 33 | PF1210-08-08-06 | steel plate | 176×190×40 | Carbon Constructional Steel | 12 | / | Rotor Assembly |

| 34 | PF1210-08-09 | Bearing outer cover | Φ320×Φ158×56 | Common Cast Steel | 1 | 23 | Rotor Assembly |

| 35 | PF1210-08-10 | Big pulley | Φ555×Φ130×263.5 | Common Cast Steel | 1 | 374 | Rotor Assembly |

| 36 | PF1210-08-11 | Big pulley caps | Φ220×Φ174×28 | Carbon Constructional Steel | 1 | Rotor Assembly | |

| 37 | PF1210-08-12 | Hold-down block | 180×110×85 | Manganese Steel | 16 | 8 | Rotor Assembly |

| 38 | PF1210-08-13 | Blow Bars | 525×300×105 | Chromium Steel | 8 | 122 | Rotor Assembly |

| 39 | PF1210-08-14 | Protective Plates | 315×130×92 | Manganese Steel | 16 | 8 | Rotor Assembly |

| 40 | PF1210-08-15 | Pins(1) | Φ32×148 | Quality Carbon Steel | 16 | / | Rotor Assembly |

| 41 | PF1210-08-16 | Pins(2) | Φ25×130 | Quality Carbon Steel | 16 | / | Rotor Assembly |

| 42 | PF1210-08-17 | Splashboard | 187.4×60×16 | Carbon Constructional Steel | 32 | / | Rotor Assembly |

| 43 | PF1210-10-01 | motor wheel 50HZ | Φ290×Φ80×263.5 | Grey Cast Iron | 1 | 117 | Rotor Assembly |

| 44 | motor wheel(60Hz) | Φ242×Φ80×263.5 | Grey Cast Iron | 1 | 86 | Rotor Assembly | |

| 45 | PF1210-04-14 | lock plate | 130×90×8 | Carbon Constructional Steel | 65 | ||

| 46 | PF1210-04-15 | Pressure plate | 130×130×40 | Carbon Constructional Steel | 65 | ||

PF1210 Impact Crusher Parts By Qiming Casting

In mining machinery and crushing equipment, the quality of accessories is directly related to the equipment’s operating efficiency and service life. As a leader in the industry, Qiming Casting has been committed to providing quality crusher parts to customers worldwide, especially for the SBM and Limining brands of impact crusher parts. With excellent product quality and perfect customer service, Qiming Casting has won the trust and praise of many customers.

Standard Replacement Parts

The impact crusher parts supplied by Qiming Casting cover a wide range of key components such as hammers, impact plates, liners, etc. Whether a standard model or a specially customized one, the company can provide precisely matched parts to meet the production needs of different customers. All the spare parts strictly follow the international advanced quality management system, from the selection of raw materials to the production process of each link, which is under strict control. We guarantee that all the accessories are 100% per the original dimensions.

Enhanced Wear Parts

As a professional manufacturer of wear parts, we have developed more wear-resistant and cost-effective products based on original parts. For example, the service life of our chrome ceramic blow bars is 2-3 times longer than that of the original high chrome blow bars.