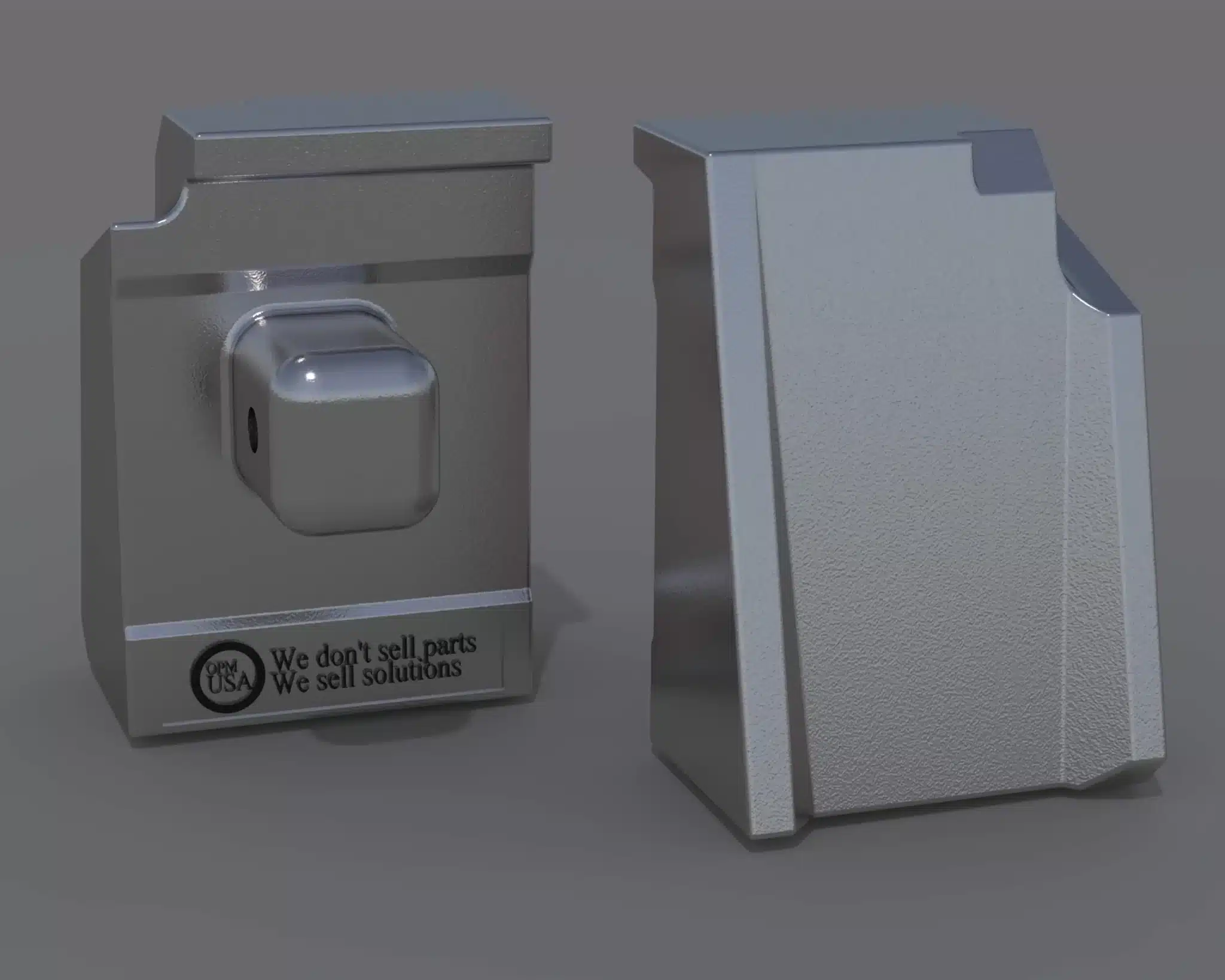

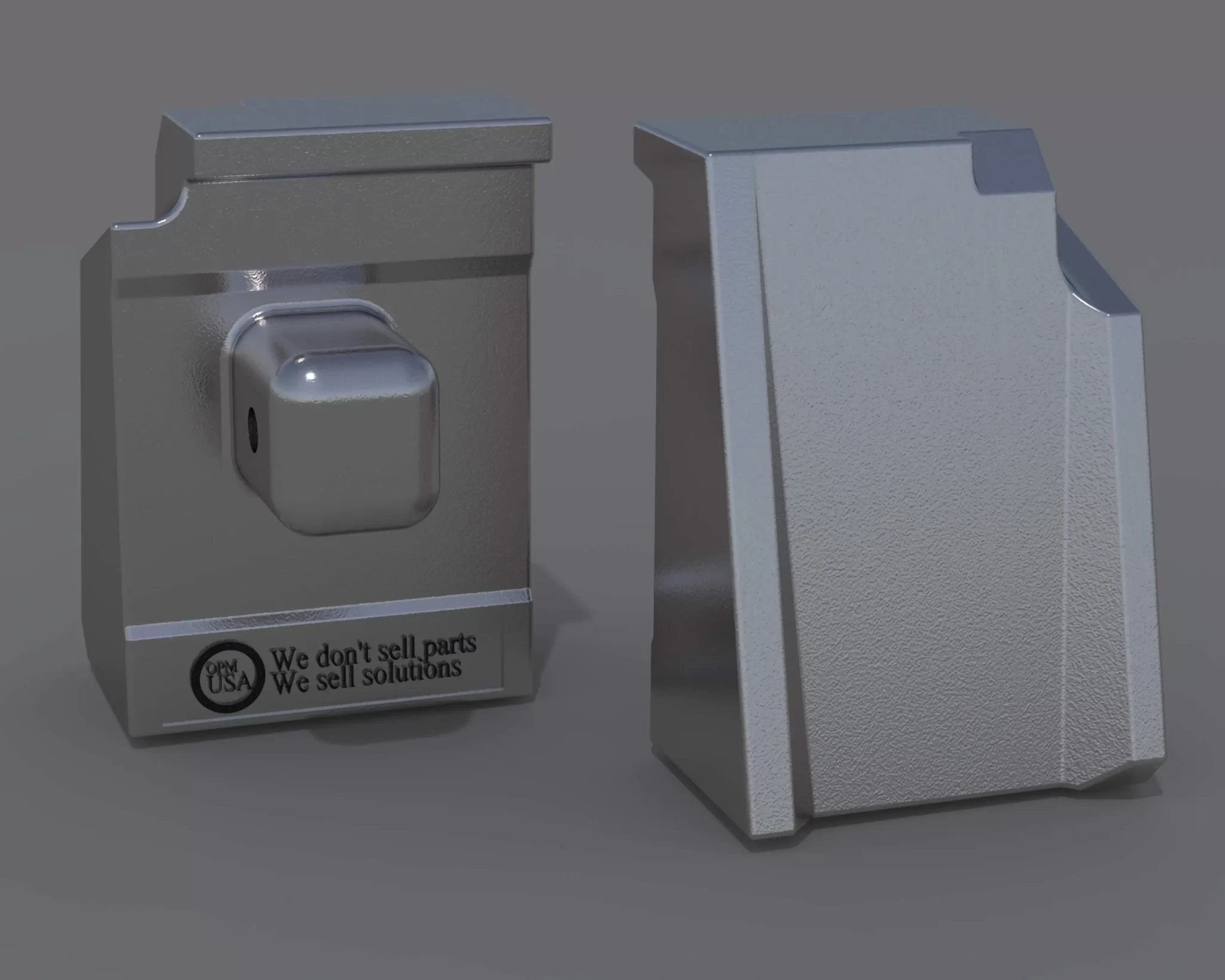

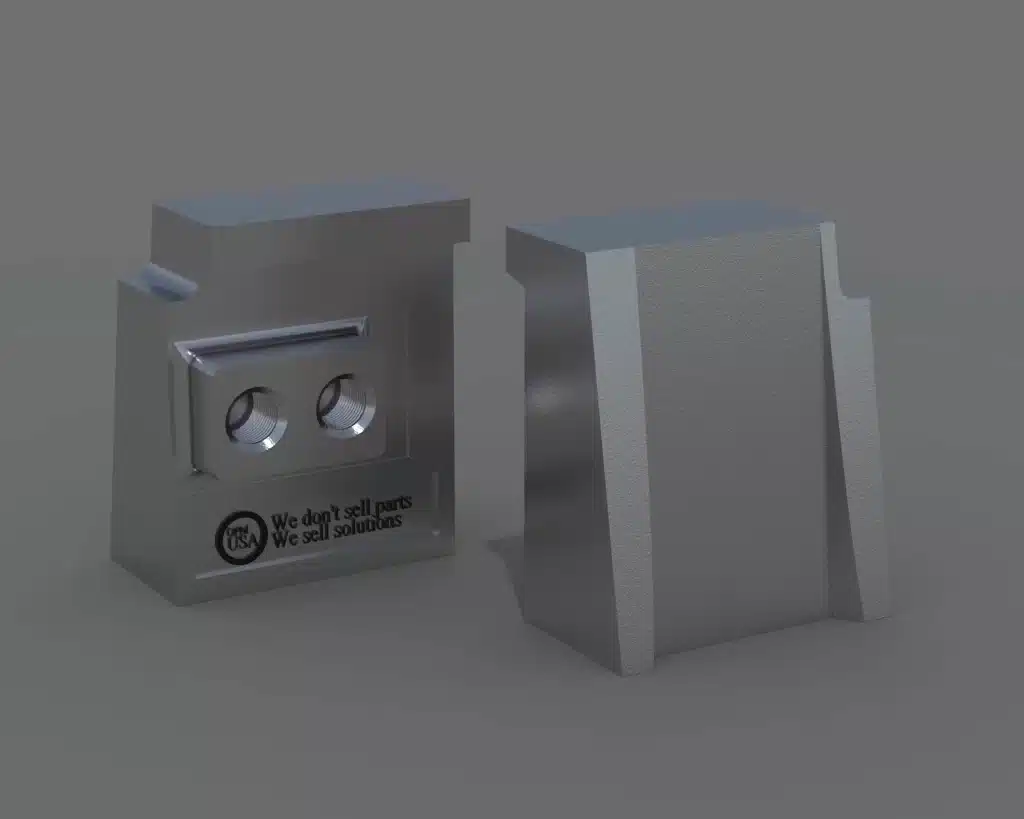

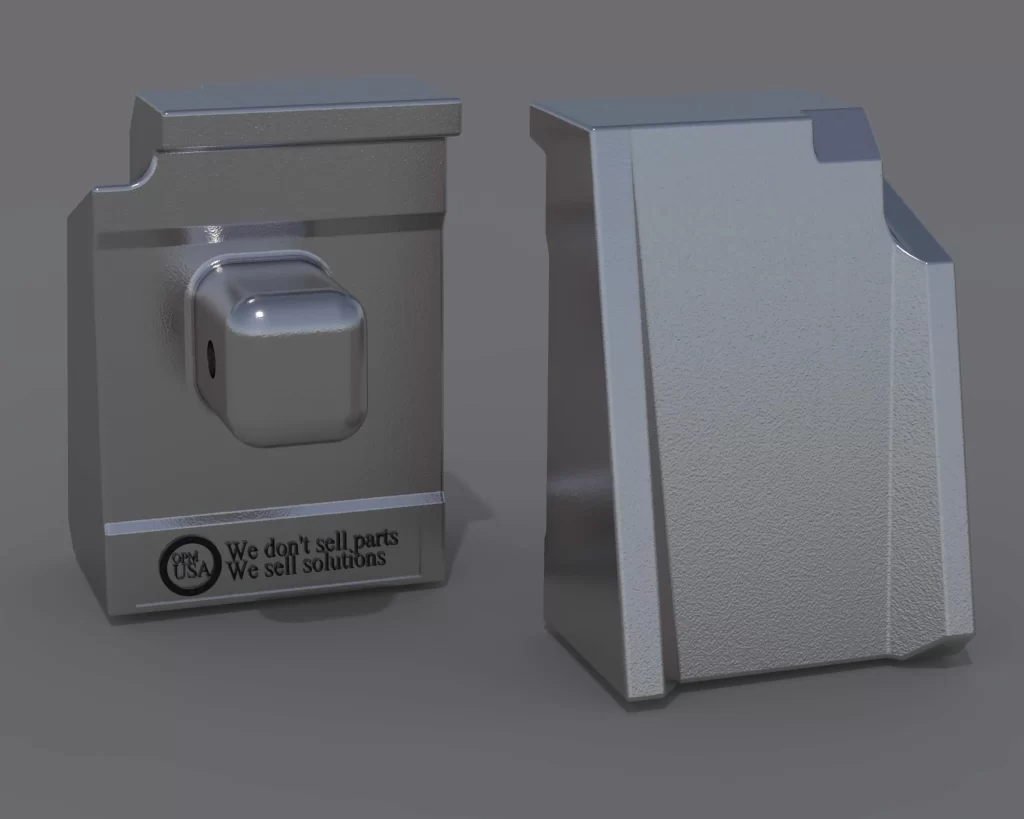

The MAG 2100 VSI crusher is designed to efficiently process various materials, including aggregates, minerals, and ores. It features a high-speed rotor with wear-resistant impact anvils or shoes that crush the material upon impact, producing well-shaped, high-quality aggregate. Qiming Casting leads the way in quality and support–beyond what you’d experience with conventional 2100 VSI crusher wear parts. Qiming Casting delivers premium replacement parts for your next MAG 2100 VSI crusher repair. We usually have the part on the shelf and ready for immediate shipment. In some instances, Qiming Casting has even improved the conventional design of the part to enhance durability and performance.

Compared with the original ceramic VSI anvils, Qiming Casting’s newly designed ceramic products have the same lifespan and are cheaper!

Qiming Casting is Your SuperStore for VSI Crusher Parts! All Qiming Casting Replacement Parts are backed by our ISO9001:2008 and are shipped only after meeting our rigorous quality standards. We are committed to meeting your replacement parts needs professionally and efficiently. Our Customer Support Department is ready to help you with a quote, check inventory, or simply answer a technical question. Talk to your Qiming Casting professional today about your specific needs!