Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

A jaw crusher is used in mines and ore processing plants. It is designed to reduce large rocks into smaller rocks or gravel.

A jaw crusher comprises several main components, including the crushing chamber, the moving jaw, and the fixed jaw. These parts help the jaw crusher crush rock and other materials.

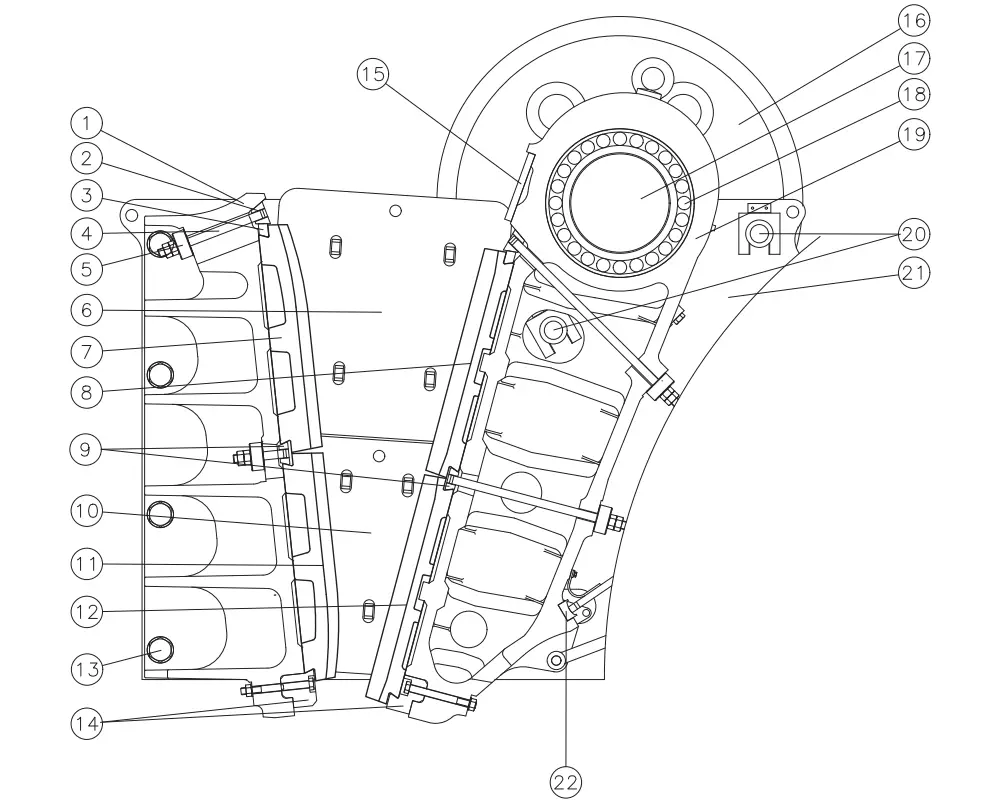

Here are the critical parts of a jaw crusher and their functions:

| Item | Description | Item | Description |

| 1 | Front frame | 12 | Moving jaw, lower |

| 2 | Upper wedge | 13 | Frame bolt |

| 3 | Filling wedge | 14 | Fixed wedge |

| 4 | Jaw die bolt | 15 | Pitman eye protection plate |

| 5 | Disc spring package | 16 | Flywheel |

| 6 | Cheek plate, upper | 17 | Eccentric shaft |

| 7 | Fixed jaw, upper | 18 | Pitman bearing |

| 8 | Moving jaw, upper | 19 | Pitman |

| 9 | Center wedges | 20 | Frame connecting rods |

| 10 | Cheek plate, lower | 21 | Side plate |

| 11 | Fixed jaw, lower | 22 | Toggle seat |

The fixed jaw is a crucial component of the jaw crusher that remains stationary. It is typically made of robust manganese steel and provides essential support to the crushing chamber. It is available in two designs, the one-piece and the two-piece design, and both options are highly reliable.

If you are looking for a trustworthy and experienced manufacturer of crusher jaw plates, look no further than Qiming Casting. Our jaw plates are made from the highest quality materials and are designed to provide optimal performance. We offer a comprehensive range of jaw plates, including standard high manganese steel fixed jaw plates, and customized options to meet your unique requirements.

Choose Qiming Casting for jaw plates that are built to last and provide exceptional crushing performance. With our expertise and commitment to quality, you can trust us to deliver the best possible solution for your needs.

Learn more about crusher jaw plates→

The moving jaw is the crucial component that is responsible for crushing. Driven by an eccentric shaft and connected to the toggle plate, it comes in two designs – a one-piece and a two-piece, both of which are made of high manganese steel.

Qiming Casting is the leading and reliable manufacturer of crusher jaw plates in China. Whether you need a standard high manganese steel or a customized moving jaw plate based on your specific requirements, Qiming Casting is the ultimate solution. Contact them today and get the best quality jaw plates for your crusher.

Learn more about crusher jaw plates→

The flywheel is an imperative component of a jaw crusher attached to the eccentric shaft. It provides significant momentum to the moving jaw, drastically reducing the energy required to crush materials. The jaw crusher flywheel is usually constructed from low-alloy, high-strength, or ZG35 casting steel.

Qiming Casting has worked extensively with numerous high-quality local foundries to produce and design a wide range of flywheels for quarries, mines, and other industrial customers. We take pride in our attention to detail and quality craftsmanship, which has resulted in the creation of top-of-the-line flywheels that are durable, efficient, and reliable.

Learn more about crusher spare parts→

The eccentric shaft is a critical component of the jaw crusher, as it drives the movement of the moving jaw, which is responsible for crushing materials within the crushing chamber. Without it, the crusher would not function properly.

The jaw crusher eccentric shaft is typically constructed using 30Mn5 casting steel for its strength and durability.

At Qiming Casting, we have collaborated with several local foundries to produce and design a wide range of high-quality, eccentric shafts for various types and brands of jaw crushers. These components are widely used in quarries, mines, and other industrial settings, and we take great pride in our ability to deliver reliable and efficient solutions to our customers.

Learn more about crusher spare parts→

The toggle plate is an indispensable element that connects the movable jaw to the eccentric shaft. Without it, the crushing process cannot proceed smoothly.

Qiming Casting has collaborated with several top-notch local foundries to design and manufacture a range of toggle plates for quarries, mines, and other industrial customers.

Our products are of the highest quality, and we take great pride in providing our customers with the best toggle plates available.

Learn more about crusher spare parts→

Qiming Casting produces wear parts for jaw crushers that are more wear-resistant, easy to install, and have a longer service life. These parts are the result of direct cooperation with jaw crusher users. Qiming Machinery also provides wear parts of different materials, including standard manganese (Mn14, Mn18, Mn22), to meet the varying needs of customers.

Qiming Casting has collaborated with local foundries to provide high-quality aftermarket spare parts, based on original drawings. We have successfully supplied replacement jaw stocks, flywheels, mainframes, and pitmans for jaw crushers, among other major components that the original equipment manufacturer has deemed obsolete.

We also offer OEM/ODM services for jaw crusher parts. Our product can be customized according to your requirements, including branding, labeling, painting colors, and packaging. You can share your design documents or ideas with our R&D team, and they will take care of the rest.