Contact us

Please leave your specific needs and contact information, and the staff will contact you as soon as possible!

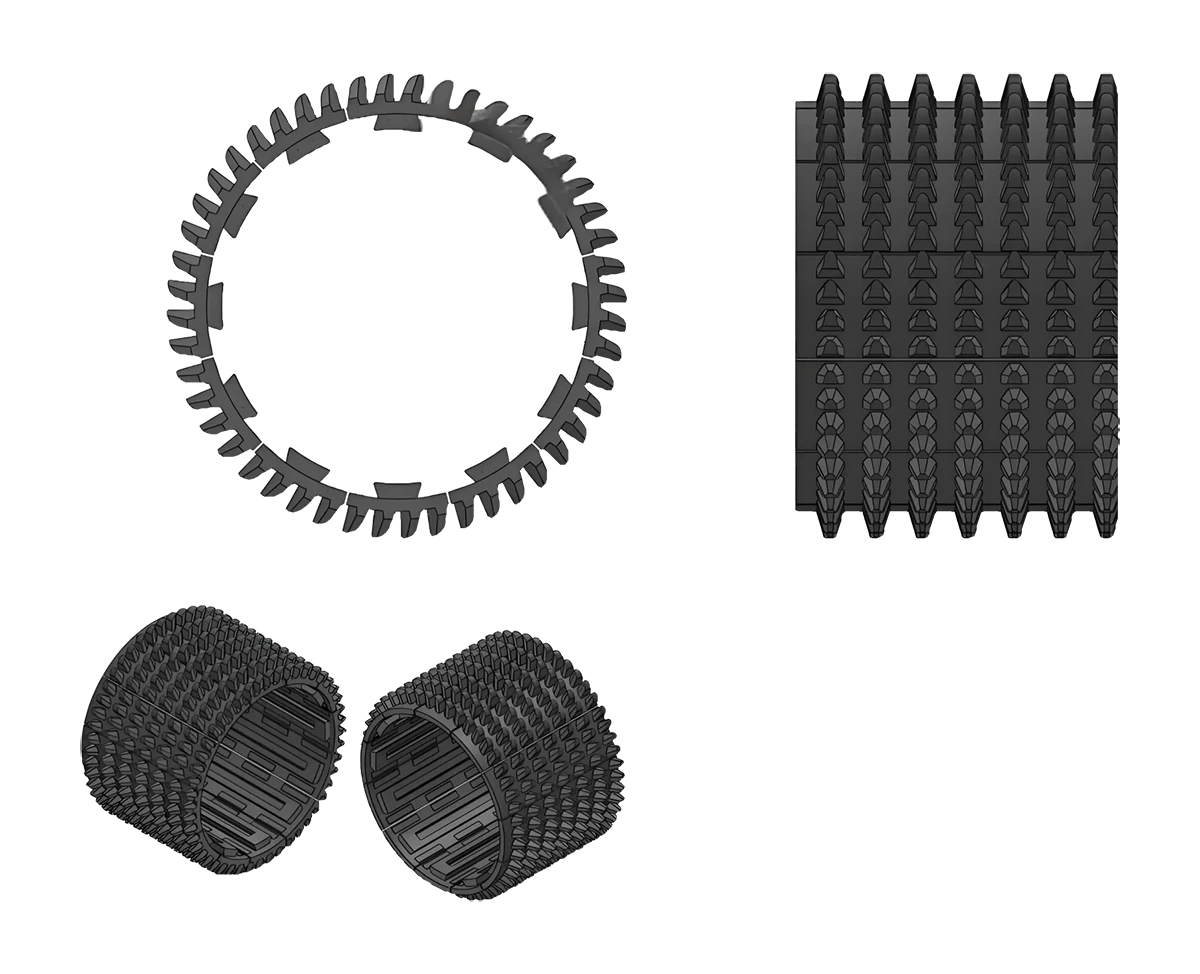

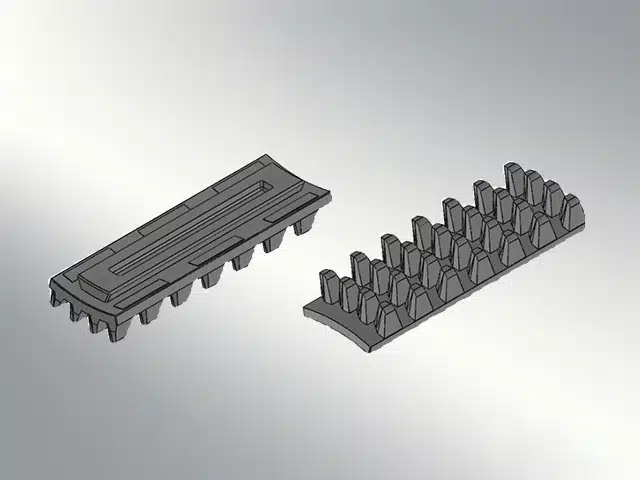

Qiming Casting specializes in producing roller crusher tooth plates featuring materials of Mn18Cr6 and bimetal composites. The Mn18Cr6 tooth plates, with their high manganese content, exhibit excellent hardness and wear resistance, making them ideal for crushing hard and abrasive materials. These tooth plates undergo a precise heat treatment process to enhance their mechanical properties, ensuring superior performance and longevity in demanding crushing applications.

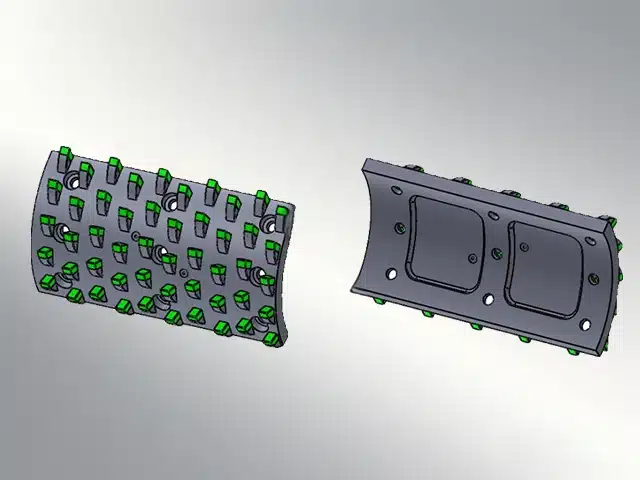

Furthermore, Qiming Casting’s bimetal composite tooth plates combine the strength and toughness of a high-quality steel base with the exceptional wear resistance of a hard-facing layer. This innovative design extends the tooth plate’s service life and reduces maintenance costs and downtime. Our bimetal tooth plates are carefully manufactured through advanced techniques such as casting and welding, ensuring a strong bond between the layers and superior resistance to impact and abrasion.

Both Mn18Cr6 and bimetal composite tooth plates offered by Qiming Casting are designed to withstand the rigors of various industrial crushing operations, including mining, quarrying, and construction. With their exceptional durability and reliability, these tooth plates are the optimal choice for enhancing the productivity and efficiency of your crushing equipment.

Mn18Cr6 steel, with its high manganese content, has unique mechanical properties. This steel typically exhibits work-hardening characteristics after being subjected to impact. Here are some main mechanical properties of Mn18Cr6 steel:

These properties make Mn18Cr6 steel suitable for making components that must withstand high impact and wear, such as crusher tooth plates and excavators’ bucket teeth. However, the specific values of mechanical properties may vary depending on different heat treatment processes and manufacturing standards.

Qiming Casting is a leading manufacturer of bimetal composite tooth plates designed specifically for roller crushers. These tooth plates are engineered using advanced materials and techniques to deliver exceptional durability and performance in demanding crushing operations. The bimetallic structure combines a hard, wear-resistant surface layer with a strong and tough base material, providing excellent resistance to abrasion and impact.