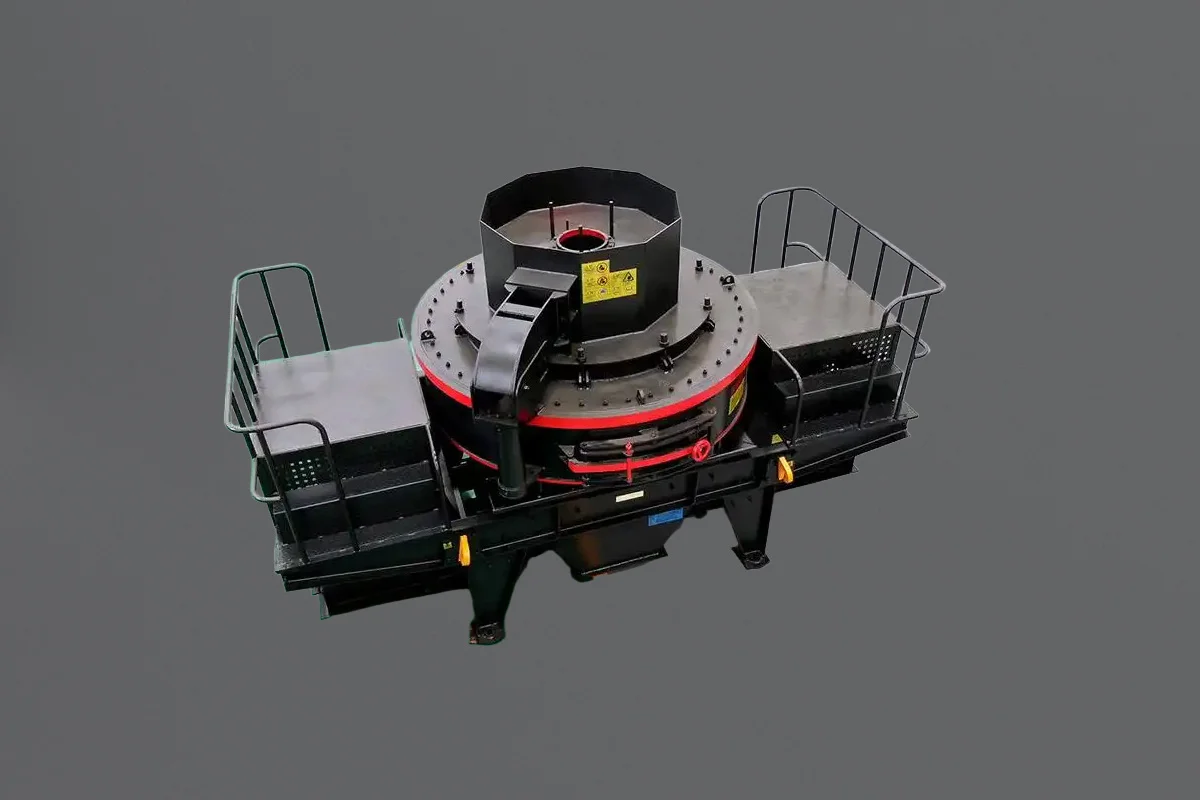

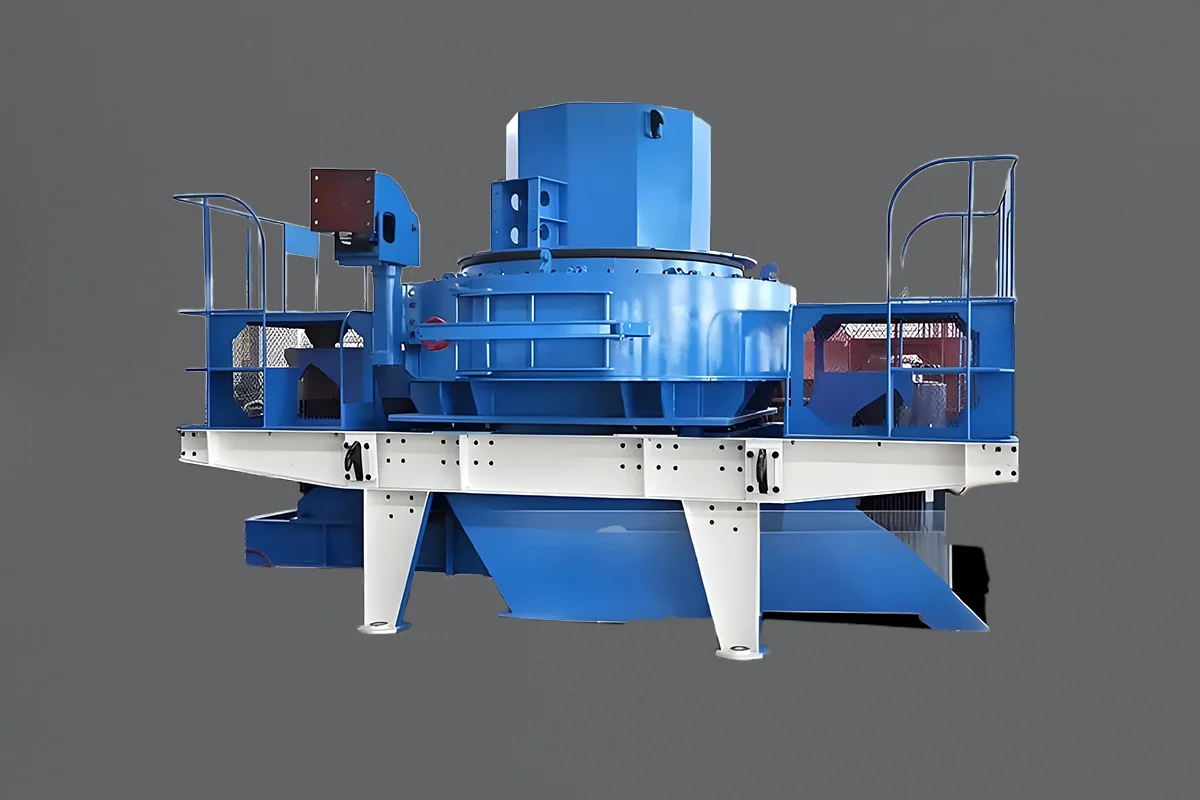

Maximize Performance with High-Quality VSI1140 Crusher Parts

The VSI1140 vertical shaft impact (VSI) crusher is a powerhouse in the mining and construction industries, designed to crush large rocks into high-quality sand and aggregates. From infrastructure projects to metallurgical processing, this machine is indispensable for achieving precise particle shaping and high-volume output. However, the intense wear on components like rotor tips, feed tubes, and wear plates demands reliable replacements to maintain operational efficiency. Qiming Casting specializes in manufacturing premium VSI1140 VSI crusher parts, engineered to extend equipment lifespan and reduce downtime.

Why the VSI1140 Crusher Stands Out

The VSI1140 crusher is renowned for its robust design and adaptability. Below are its critical specifications:

- Capacity

- Cascade & Center Feeding: 450–520 T/H

- Full Center Feeding: 225–260 T/H

- Feed Size

- Sand-Making Mode: ≤45mm (soft materials ≤50mm, hard materials ≤45mm)

- Shaping Mode: ≤55mm (ideal for stone shaping)

- Output Size

- Adjustable Range: 0–5mm (85% under 5mm in single pass)

- Power & Speed

- Rotor Speed: 1180–1310 RPM

- Motor Power: 400kW (Dual Motor Drive)

- Dimensions & Weight

- Machine Size: 5000×2700×3300mm

- Total Weight: 25.6 Tons

These specifications make the VSI1140 a top choice for industries requiring high efficiency and precision. Its global demand spans markets in the Middle East, Southeast Asia, Africa, and South America, where durability and performance are non-negotiable.

Qiming Casting: Your Trusted Partner for VSI1140 Crusher Parts

As a leading supplier of crusher wear parts, Qiming Casting provides VSI1140 VSI crusher components crafted from advanced materials like high-chromium iron (27% Cr), ZGMn13Cr2, and alloy steel. Our parts are built to withstand extreme abrasion and impact, ensuring your crusher operates at peak productivity.

Key Replacement Parts We Manufacture:

- Rotor Tips & Back-Up Tips: Protect the rotor assembly from rapid wear.

- Feed Tubes & Distributor Cones: Ensure optimal material distribution for uniform crushing.

- Upper/Lower Wear Plates: Guard critical zones against abrasive damage.

- Impact Blocks & Guard Rings: Maintain structural integrity under heavy loads.

Every component undergoes rigorous quality control, including hardness testing and dimensional inspections, to guarantee OEM-level precision and longevity.

Qiming Casting’s VSI1140 Crusher Parts Catalogue:

| A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|

| No. | Name | Drawing Number | Spec | Material | Qty | Unit | Unit Weight (Kg) |

| 1 | Motor Pulley | VSI1140-2-101 | HT | 2 | Piece | 162 | |

| 2 | Main Shaft Pulley | VSI1140-6-101 | HT | 1 | Piece | 373.5 | |

| 3 | Bearing Locating Sleeve | VSI1140-6-107 | HT | 1 | Piece | 90 | |

| 4 | Bearing Sleeve | VSI1140-6-106 | QT | 1 | Piece | 707.5 | |

| 5 | Upper Bearing Sleeve Positioning Disc | VSI1140-5-117 | ZG | 1 | Piece | 180 | |

| 6 | Lower Bearing Sleeve Positioning Disc | VSI1140-5-116 | ZG | 1 | Piece | 148 | |

| 7 | Lower Seal Sleeve | VSI1140-6-102 | ZG | 1 | Piece | 14.5 | |

| 8 | Lower Bearing Cover | VSI1140-6-103 | ZG | 1 | Piece | 50.5 | |

| 9 | Upper Bearing Cover | VSI1140-6-110 | ZG | 1 | Piece | 60.5 | |

| 10 | Rotor Guard Ring | VSI1140-8-102 | ZG65Mn | 1 | Piece | 57 | |

| 11 | Feed Liner Ring | VSI1140-3-101 | ZGMn13Cr2 | 12 | Piece | 4.7 | |

| 12 | Impact Block | VSI1140-3-102 | ZGMn13Cr2 | 48 | Piece | 35.5 | |

| 13 | Upper Impact Plate | VSI1140-3-104 | ZGMn13Cr2 | 24 | Piece | 16.6 | |

| 14 | Hopper Liner Ring | VSI1140-3-111 | ZGMn13Cr2 | 5 | Piece | 2 | |

| 15 | Lower Impact Plate | VSI1140-3-109 | ZGMn13Cr2 | 24 | Piece | 16.6 | |

| 16 | Upper Flow Plate | VSI1140-8-103 | ZGMn13Cr2 | 3 | Piece | 13.3 | |

| 17 | Lower Flow Plate | VSI1140-8-104 | ZGMn13Cr2 | 3 | Piece | 19.5 | |

| 18 | Wear Plate | VSI1140-8-107 | ZGMn13Cr2 | 3 | Piece | 2.3 | |

| 19 | Feed Pipe | VSI1140-3-110 | High Chromium Iron | 1 | Piece | 20 | |

| 20 | Impact Block | VSI1140-8-106 | High Chromium Iron | 9 | Piece | 2 | |

| 21 | Distributor Cone | VSI1140-8-105 | High Chromium Iron | 1 | Piece | 82.5 | |

| 22 | Guard Block | VSI1140-8-108 | High Chromium Iron | 9 | Piece | 2.5 | |

| 23 | Hammer Head | VSI1140-8-2-101 | 42CrMo + Alloy Strip | 3 | Piece | 4.95 | |

| 24 | Main Shaft | VSI1140-6-108 | 35CrMo | 1 | Shaft | 280 | |

| 25 | Bearing Sleeve Assembly | VSI1140-6 | 1 | Piece | |||

| 26 | Rotor Assembly | VSI1140-8 | 1 | Piece | |||

| 27 | Upper Dust Cover | VSI1140-6-111 | ZG | 1 | Piece | ||

| 28 | Lower Bush | VSI1140-3-4-1-102 | 1 | Piece | |||

| 29 | Upper Bush | VSI1140-3-4-1-104 | 1 | Piece | |||

| 30 | Hydraulic Manifold | HT200 | 1 | Piece | |||

| 31 | Impeller | VSI1140-8-1-1 | 1 | Piece |

Why Choose Qiming Casting?

- Material Science Expertise

We use high-chromium iron and ZGMn13Cr2 alloys, proven to deliver 2–3x longer service life compared to standard materials. - Custom Solutions

Tailor parts to your specific operational needs, including modified geometries or material compositions. - Global Logistics Network

With warehouses in the USA, Europe, and Asia, we ensure fast delivery to minimize your downtime. - Cost Efficiency

Competitive pricing without compromising quality—save up to 30% compared to OEM alternatives. - Proven Track Record

Trusted by clients in over 20 countries, including major mining and cement companies.

Applications Across Industries

- Mining: Process ores and aggregates with minimal maintenance.

- Cement Production: Achieve consistent sand quality for concrete mixtures.

- Quarrying: Optimize stone shaping for road construction and landscaping.

Upgrade Your Crusher’s Performance Today

Don’t let worn-out parts slow down your operations. Qiming Casting’s VSI1140 crusher components are designed to enhance productivity, reduce energy consumption, and lower total ownership costs.

Contact us now for a free quote or to discuss custom requirements. Let us help you keep your VSI1140 crusher running like new!